16

Rossi

Operating instructions − UTD.045.06-2013.00_TR_EN

TR

EN

Unless otherwise agreed in the order, products are adequately

packed: on pallet, protected with a polyethylene film, wound with

adhesive tape and strap (bigger sizes); in carton pallet, wound with

adhesive tape and strap (smaller sizes); in carton boxes wound with

tape (for small dimensions and quantities). If necessary, gear redu-

cers are conveniently separated by means of anti-shock foam cells

or of filling cardboard.

Do not stock packed products on top of each other.

4 - Storing

Surroundings should be sufficiently clean, dry and free from ex-

cessive vibrations (

v

eff

≤

0,2 mm/s) to avoid damage to bearings (ex-

cessive vibration should also be guarded during transit, even if within

wider range) and ambient storage temperature should be 0

÷

+40 °C:

peaks of 10 °C above and below are acceptable.

The gear reducers filled with oil must be positioned according to the

mounting position mentioned on the order during transport and storage.

Every six months rotate the shafts (some revolutions are sufficient)

to prevent damage to bearings and seal rings.

Assuming normal surroundings and the provision of adequate pro-

tection during transit, the unit is protected for storage up to 1 year.

For a 2 year storing period in normal surroundings it is necessary to

pay attention also to following instructions:

– generously grease the sealings, the shafts and the unpainted

machined surfaces, if any, and periodically control conservation

state of the protective anti-rust oil;

– for gear reducers and gearmotors supplied without oil: comple-

tely fill the gear reducers with lubrication oil and verify the speci-

fied level before commissioning.

For storages longer than 2 years or in aggressive surroundings or

outdoors, consult Rossi.

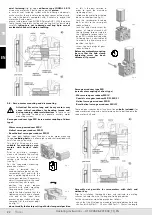

5 - lnstallation

5.1 - General

Before the installation, verify that:

– there were no damages during the storing or the transport;

– design is suitable to the environment (temperature, atmosphere,

etc.);

– electrical connection (power supply, etc.) corresponds to motor

name plate data;

– used mounting position corresponds to the one stated in name

plate.

Attention!

When lifting and transporting the gear redu-

cer or gearmotor use through holes or tapped holes of the

gear reducer housing; be sure that load is properly balan-

ced and provide lifting systems, and cables of adequate

section. If necessary, gear reducer and gearmotor masses are sta-

ted in Rossi technical catalogs.

Be sure that the structure on which gear reducer or gearmotor is

fitted is plane, levelled and sufficiently dimensioned in order to

assure fitting stability and vibration absence (vibration speed

v

eff

≤

3,5 mm/s for

P

N

≤

15 kW and

v

eff

≤

4,5 mm/s for

P

N

> 15 kW are

acceptable), keeping in mind all transmitted forces due to the mas-

ses, to the torque, to the radial and axial loads.

For the dimensions of fixing screws of gear reducer feet and the

depth of tapped holes consult the Rossi technical catalogues.

Carefully select the length of fastening bolts when using tapped

holes for gear reducer fitting, in order to assure a sufficient meshing

thread length for the correct gear reducer fitting to the machine

without breaking down the threading seat.

Attention! Bearing life and good shaft and cou-

pling running depend on alignment precision

between the shafts.

Carefully align the gear reducer

with the motor and the driven machine (with the aid of

shims if need be, for gear reducers size ≥ 400 use level tapped

holes), interposing flexible couplings whenever possible.

Incorrect alignment

may cause

breakdown of shafts and/or

bearings

(which may cause overheatings) which may represent

heavy danger for people

.

Do not use motor eyebolts when lifting the gearmotors.

Position the gear reducer or gearmotor so as to allow a free pas-

sage of air for cooling both gear reducer and motor (especially at

their fan side).

Avoid: any obstruction to the air flow; heat sources near the gear

reducer that might affect the temperature of cooling air and of gear

reducer (for radiation); insufficient air recycle and applications hinder-

ing the steady dissipation of heat.

Mount the gear reducer or gearmotor so as not to receive vibrations.

Mating surfaces (of gear reducer and machine) must be clean and suf-

ficiently rough (approximately

R

a ≥ 6,3

m

m) to provide a good friction

coefficient: remove by a scraper or solvent the eventual paint of gear

reducer coupling surfaces.

When external loads are present use pins or locking blocks, if ne-

cessary.

When fitting gear reducer and machine and/or gear reducer and

eventual flange

B5

it is recommended to use

locking adhesives

on the fastening bolts (also on flange mating surfaces).

Before wiring-up the gearmotor make sure that motor voltage

corre-sponds to input voltage. If direction of rotation is not as

desired, invert two phases at the terminals.

Y-

D

starting should be adopted for no-load starting (or with a very

small load) and for smooth starts, low starting current and limited

stresses, if requested.

If overloads are imposed for long periods or if shocks or danger of

jamming are envisaged, then motor-protection, electronic torque

li-miters, fluid couplings, safety couplings, control units or other

similar devices should be fitted.

Usually protect the motor with a thermal cut-out

however,

where duty cycles involve a high number of on-load starts, it is

necessary to utilise

thermal probes

for motor protection (fitted on

the wiring); magnetothermic breaker is unsuitable since its thresh-

old must be set higher than the motor nominal current of rating.

Connect thermal probes, if any, to auxiliary safety circuits

.

Use varistors and/or RC filters to limit voltage peaks due to con-

tactors.

When gear reducer is equipped with a backstop device, see ch. 5.5

and provide a protection system where a backstop device breaking

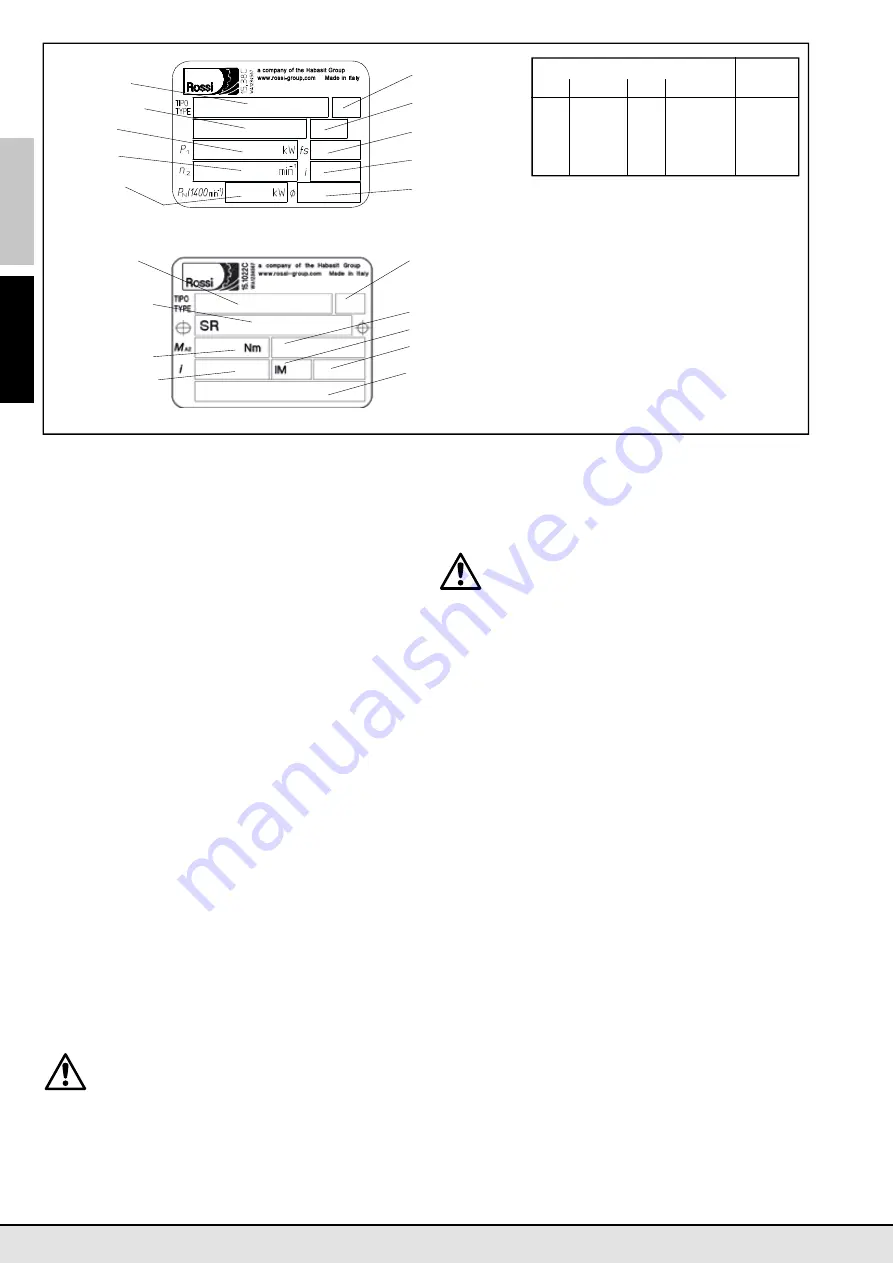

Designation (see

table on the right)

Non-standard designs

Motor power

Gearmotor

output speed

Gear reducer

nominal power

Two months and year

of manufacture

Mounting position

(when differing from

IM B3 or B5)

Gearmotor

service factor

Transmission

ratio

Ø Flange - motor

shaft

Fig. 1 (for more information, see Rossi technical catalogs; consult us).

Designation

Product

Machine Train of gears

Size

Esecuzione

R, MR

V, IV, 2IV

32 ... 250 UO ...

Worm

R, MR

2I, 3I

32 ... 180 FC ..., PC ..., UC ...

Coaxial

R, MR

I, 2I, 3I, 4I

40 ... 631 UP ...

Helical

R, MR

CI, ICI, C2I, C3I 40 ... 631 UO ...

Bevel helical

R

C

80 ... 320 PO ..., FO ...

Right angle

R

2I

85 ... 250 OP

Shaft mounted

Note

: Starting from 04/05/2010 the company name ROSSI MOTORIDUTTORI S.p.A. has been changed into Rossi S.p.A., and the nameplates have been updated accordingly.

Type of machine, train of

gears, size, design

Non-standard design

codes (SR = gear

reducer for automation)

Maximum accelerating

torque on low speed

shaft

Transmission ratio

Two-month and year of

manufacturing

Serial code

Mounting position

Angular backlash on low

speed shaft

Coupling dimension on

input side