15

Rossi

Operating instructions − UTD.045.06-2013.00_TR_EN

TR

EN

Contents

1 - General safety instructions

15

2 - Operating conditions

15

3 - How supplied

15

3.1 - Receipt

15

3.2 - Name plate

15

3.3 - Painting

15

3.4 - Protections and packing

15

4 - Storing

16

5 - Installation

16

5.1 - General

16

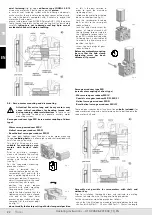

5.2 - Fitting of components to shaft ends

17

5.3 - Shaft-mounting

17

5.4 - Hollow low speed shaft

17

5.5 - Backstop device

20

5.6 - Shrink disc

20

6 - Lubrication

20

6.1 - General

20

6.2 - Lubrication table

18

6.3 - Extruder support lubrication

20

Operating instructions gear reducers and gearmotors

7 - Cooling system

20

7.1 - Cooling by fan

20

7.2 - Water cooling by coil

20

7.3 - Independent cooling unit

20

8 - Commissioning

21

9 - Maintenance

21

9.1 - General

21

9.2 - Coil

21

9.3 - Seal rings

21

9.4 - IEC motor mounting and dismounting

21

9.5 - Servo motor mounting and dismounting

22

9.6 - Bearings

23

9.7 - Metal filler plug with filter and valve

23

10 - Sound levels

23

Painting table

24

Table of tightening torques for axial fastening

bolts and shrink disc

24

Table of tightening torques for fastening bots (foot,

flange, hub clamps and flexible half-coupling bolts)

24

Table of tightening torques for plugs

24

Gear reducer troubles: causes and

corrective actions

25

Recycling

(keeping in mind the instructions in force):

– the elements of housing, gear pairs, shafts and bearings of gear

reducer must be transformed into steel scraps. The elements in

grey cast iron will be subjected to the same treatment if

there is no particular instruction;

– the worm wheels are made in bronze and must be treated

adequately;

– exhausted oils must be recycled and treated according to the

instructions.

The paragraphs marked with present symbol contain

dispositions to be strictly respected in order to assure

personal

safety

and to avoid any

heavy damages

to

the machine or to the system (e.g.: works on live parts, on

lifting machines, etc.); the responsible for the installation or mainte-

nance must scrupulously

follow all instructions contained in

present handbook.

1 - General safety instructions

Gear reducers and gearmotors present dangerous parts because

they may be:

– live;

– at temperature higher than +50 °C;

– rotating during the operation;

– possibly noisy (sound levels > 85 dB(A)).

An incorrect installation, an improper use, the removing or discon-

nection of protection devices, the lack of inspections and maintenan-

ce, improper connections may cause severe personal injury or pro-

perty damage. Therefore the component must be moved, installed,

commissioned, handled, controlled, serviced and repaired

exclusi-

vely by responsible qualified personnel

(definition to IEC 364).

It is recommended to pay attention to all instructions of present

handbook, all instructions relevant to the system, all existing safety

laws and standards concerning correct installation.

Attention!

Components in non-standard design or with constructi-

ve variations may differ in the details from the ones described here

following and may require additional information.

Attention!

For the installation, use and maintenance of the electric

motor (standard, brake or non-standard motor) and/or the electric

supply device (frequency converter, soft-start, etc.) and accessories, if

any (flow indicators, independent cooling unit, thermostat, ecc) con-

sult the attached specific documentation. If necessary, require it.

Attention!

For any clarification and/or additional information con-

sult Rossi and specify all name plate data.

Gear reducers and gearmotors of present handbook are normally

suitable for installations in industrial areas:

additional protection

measures,

if necessary for different employs, must be adopted

and assured by the person responsible for the installation.

IMPORTANT: the components supplied by Rossi must be incorpo-

rated into machinery and

should not be commissioned before

the machinery in which the components have been incor-

porated conforms to:

–

Machinery directive 2006/42/EC and subsequent upda-

tings; in particular, possible safety guards for shaft ends

not being used and for eventually accessible fan cover

passages (or other) are the Buyer’s responsibility;

–

«Electromagnetic compatibility (EMC)» directive 2004/108/

EC and subsequent updatings.

When operating on gear reducer (gearmotor) or on components

connected to it

the machine must be at rest:

disconnect motor

(including auxiliary equipments) from power supply, gear reducer

from load, be sure that safety systems are on against any accidental

starting and, if necessary, pre-arrange mechanical locking devices

(to be removed before commissioning).

If deviations from normal operation occur (temperature increase,

unusual noise, etc.) immediately switch off the machine.

The products relevant to this handbook correspond to the technical

level reached at the moment the handbook is printed. Rossi reser-

ves the right to introduce, without notice, the necessary changes

for the increase of product performances.

2 - Operating conditions

Gear reducers are designed for industrial applications according to

name plate data, at ambient temperature 0

4

+40 °C (with peaks at

-10 °C and +50 °C), maximum altitude 1 000 m.

Not allowed running conditions: application in aggressive envi-

ronments having explosion danger, etc. Ambient conditions must

comply with specifications stated on name plate.

3 - How supplied

3.1 - Receipt

At receipt verify that the unit corresponds to the one ordered and

has not been damaged during the transport, in case of damages,

report them immediately to the courier.

Avoid commissioning gear reducers and gearmotors, that are even

if slightly damaged.

3.2 - Name plate

Every gear reducer presents a name plate in anodised aluminium

containing main technical information relevant to operating and

constructive specifications and defining, according to contractual

agreements, the application limits (see fig. 1); the name plate must

not be removed and must be kept integral and readable. All name

plate data must be specified on eventual spare part orders.

3.3 - Painting

Products are painted according to the painting table shown on page 24.

Before adding further coats of paint (use dual-compound paints only),

properly protect the seal rings (which must neither be damaged nor

painted), degrease and sand the gear reducer (or gearmotor) surfaces.

3.4 - Protections and packing

Overhanging free shaft ends and hollow shafts are treated with protec-

tive anti-rust long life oil and protected with a plastic (polyethylene)

cap (only up to D

≤

48 mm for overhanging shafts, D

≤

10 mm for

hollow shafts). All internal parts are protected with protective anti-rust oil.