96-0012 rev G

11

June 2003

O

M

PERATOR’S

ANUAL

A u t o m a t i c

A u t o m a t i c

A u t o m a t i c

A u t o m a t i c

P a l l e t C h a n g e r

P a l l e t C h a n g e r

CAUTION

!

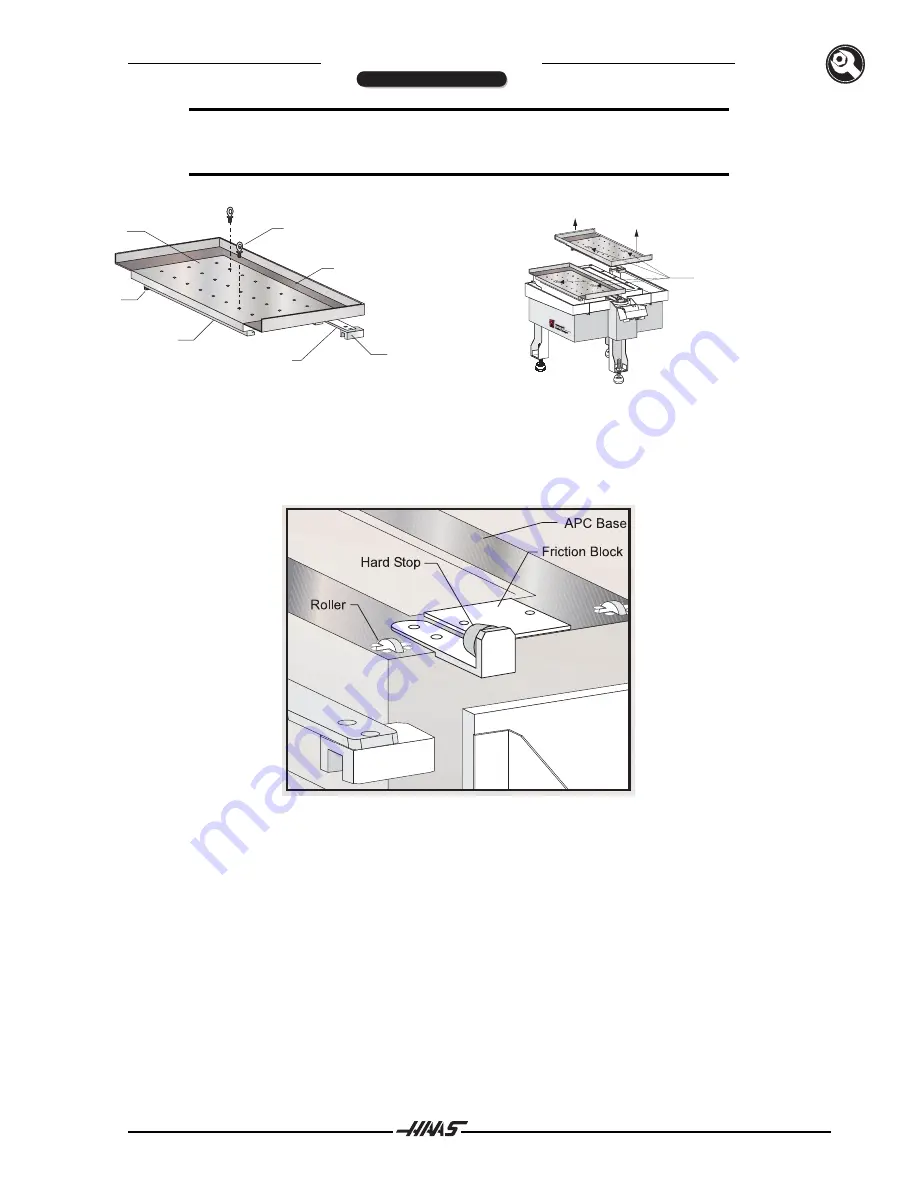

Use extreme caution when moving the pallets; each pallet weighs

300 lbs., and can cause serious injury. Be careful not to damage the

pallets or the APC rollers.

1/2“ - 13 Eyebolts

Pallet

Pallet Drive Leg

Drive Leg Detent

Drip Pan

Clamp Rail

Wiper

(2)

(2)

1

2

Remove pallet shipping bolts

and install 1/2”-13 plugs. Use

Loctite. Visually check to verify

that plugs do not extend into

roller channels.

It is important to

install the plugs to prevent chips

from falling under the pallets and

causing possible damage.

Figure 3.11 Lifting eyebolt locations.

Figure 3.12 Pallet placement.

19.

Pull the pallets onto the friction blocks and against the hard stop (see Figure 3.13). Rotate the

chain slightly, using the chain position adjustment tool, to allow each drive leg detent to clear the

chain drive roller.

Figure 3.13 View of APC base showing friction block and hard stop.

20.

Power OFF the VMC.

WARNING!

WARNING!

WARNING!

WARNING!

WARNING!

This will cause the automatic door to fall. Keep hands clear.

21

. Remove the jumper from the Fifth Axis (B) port on the side of the VMC control cabinet (see Figure

3.2), and insert the APC amphenol connector into this port. Tie-wrap the cable to the door switch

cable and the air hoses at the rear of the VMC.

22.

Screw the air blast hose into the APC. Remove the piece of tubing from the top fitting of the VMC

lube/air panel cross fitting, and replace it with the APC air hose (see Figure 3.14).

INSTALLATION