9

2

Installing the firewall

WARNING!

Keep the tamper-proof seal on a mounting screw on the chassis cover intact, and if you want to open

the chassis, contact H3C for permission. Otherwise, H3C shall not be liable for any consequence.

The firewall view varies by model. The following figures are for illustration only. This document uses

an F1080 firewall as an example.

Installation flow

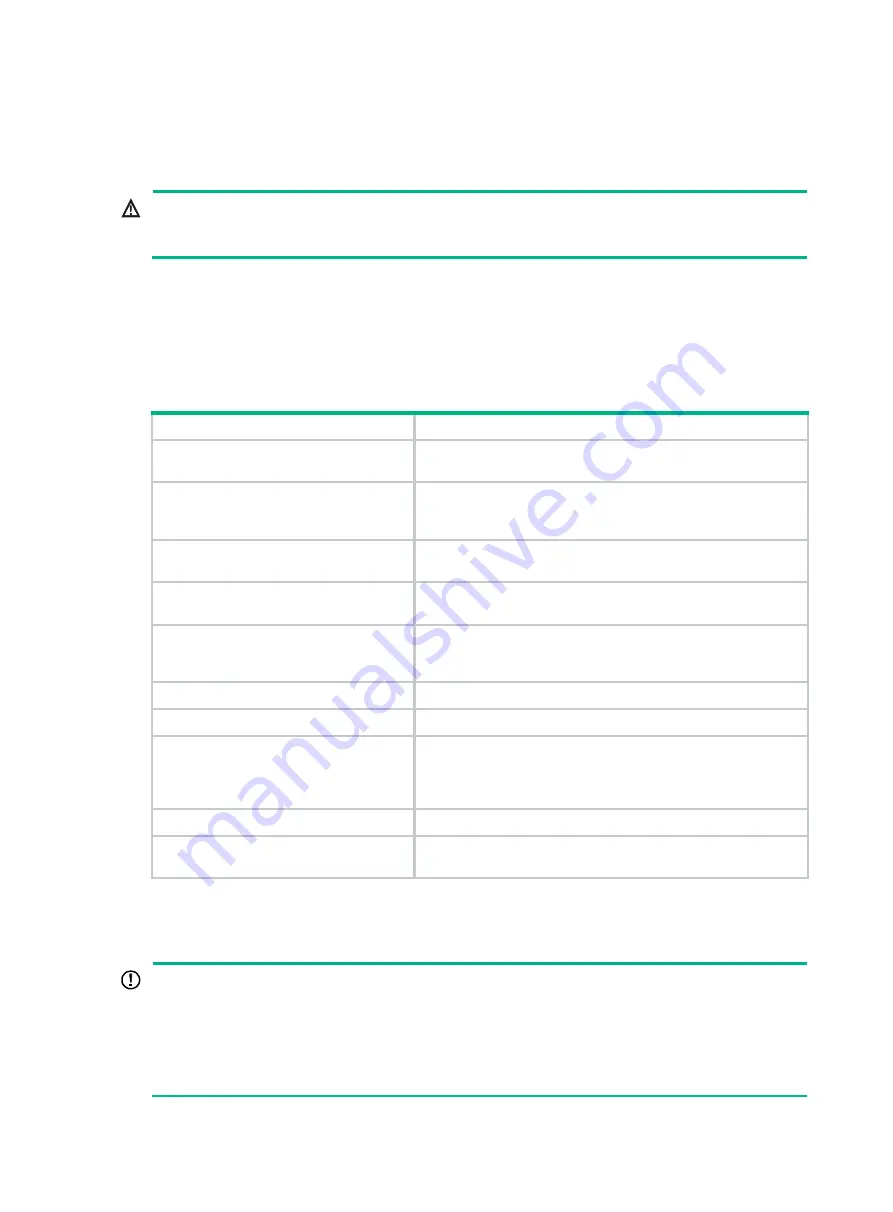

Table2-1 Installation flow for the F10X0 firewalls

Step

Description

1.

Start

Before installation, make sure all requirements on the checklist

are met and the firewall is powered off.

Mounting the firewall on a

workbench

Verify that the workbench is sturdy and reliably grounded.

Ensure a minimum clearance of 100 mm (3.94 in) around the air

inlet and outlet vents of the chassis.

Installing the firewall in a standard

19-inch rack

To avoid bodily injury and device damage, use a minimum of

two people to rack-mount the device.

4.

Before installation, make sure the firewall and rack are reliably

grounded and you wear an ESD wrist strap.

5.

Before you install a power module, make sure the power

module is not connected to any power source and the grounding

cable of the firewall is connected reliably.

6.

Installing an interface module

Install compatible interface modules on the firewall.

7.

Install compatible drives on the firewall.

8.

The firewall provides various ports. Choose compatible

transceiver modules and cables as required. To avoid bodily

injury or device damage, read the restrictions and guidelines

carefully before connection.

9.

Connect compatible power cords to the power modules.

10.

Verify that the firewall is installed securely and reliably

grounded, and that the power modules are as required.

Mounting the firewall on a workbench

IMPORTANT:

•

Ensure good ventilation and a minimum clearance of 100 mm (3.94 in) around the chassis for

heat dissipation.

•

Avoid placing heavy objects on the firewall.

•

To stack firewalls, make sure a minimum vertical distance of 15 mm (0.59 in) is available between

two adjacent firewalls.