9

GROWSPAN

™

ROLLING PREMIUM HIGH TUNNELS

Revision date: 01.01.16

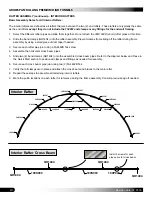

LAYOUT BUILDING POSITION ON SITE

To fully use the rolling feature of this building, you must

provide adequate distance for the building to move.

Minimum distance to clear the original location of the

building is twice the building length.

For example, if the building is 48' long, site must be at

least 96' long to allow the building to roll from one position

to another. Building is equipped with enough 1.66" pipe to

create a track that is twice the length of the building frame.

To move the building in the same direction, track can be

disassemble, reassembled, and attached to the desired

end of the track that the building rests on.

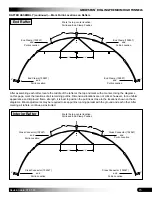

The information that follows shows using ground cloth

(included) to prevent vegetation from growing around

the track path. Basic steps to layout the track include the

following:

1. Determine the best position on the site for the

assembled building. Consider where the rafters will be

assembled and how these will be transported to the

frame assembly area.

2. A level site is required for best results. Remove

debris, obstacles, and other objects that can prevent

the 1.66" track pipe from running tight to the ground.

If necessary, prepare the track portion of the site by

leveling the bumps and hills and filling the ditches. The

straighter the track runs, the easier it will be to roll the

assembled building.

Allow 24" of clearance on each side of the track pipe to

more easily access the frame and frame anchors when

moving the building.

3. Roll out the ground cloth and stake the cloth to the site

using the fabric staples. Drive one (1) stake every 4'

along each outer edge of the ground cloth. See next

page for photos.

4. Locate the 1.66" pipe (166S099) used for the track.

Pipes are connected; however, joints are not secure

with any fasteners. Doing so will interfere with the metal

castors and prevent rolling. Joints can be secured with

a couple layers of duct tape if desired. Additionally,

pipes are not secured to the site.

5. Drive a couple of stakes to mark the width of the

building and the beginning of the track. Connect a few

pipes and place these in position on the site. Assemble

only enough to allow for the assembly of the first few

bays of the frame. Pipe can be added as the frame is

assembled. This prevents running over the track pipe

during assembly.

6. After setting a few track pipes in place, continue with

the assembly of the rafters and frame.

Photo shows stakes at the width of the frame and at the

beginning of the track positions.

Track Location

Track Location

Width of Frame