-30-

Model G0686 (Mfd. Since 01/15)

SECTION 7: SERVICE

Troubleshooting

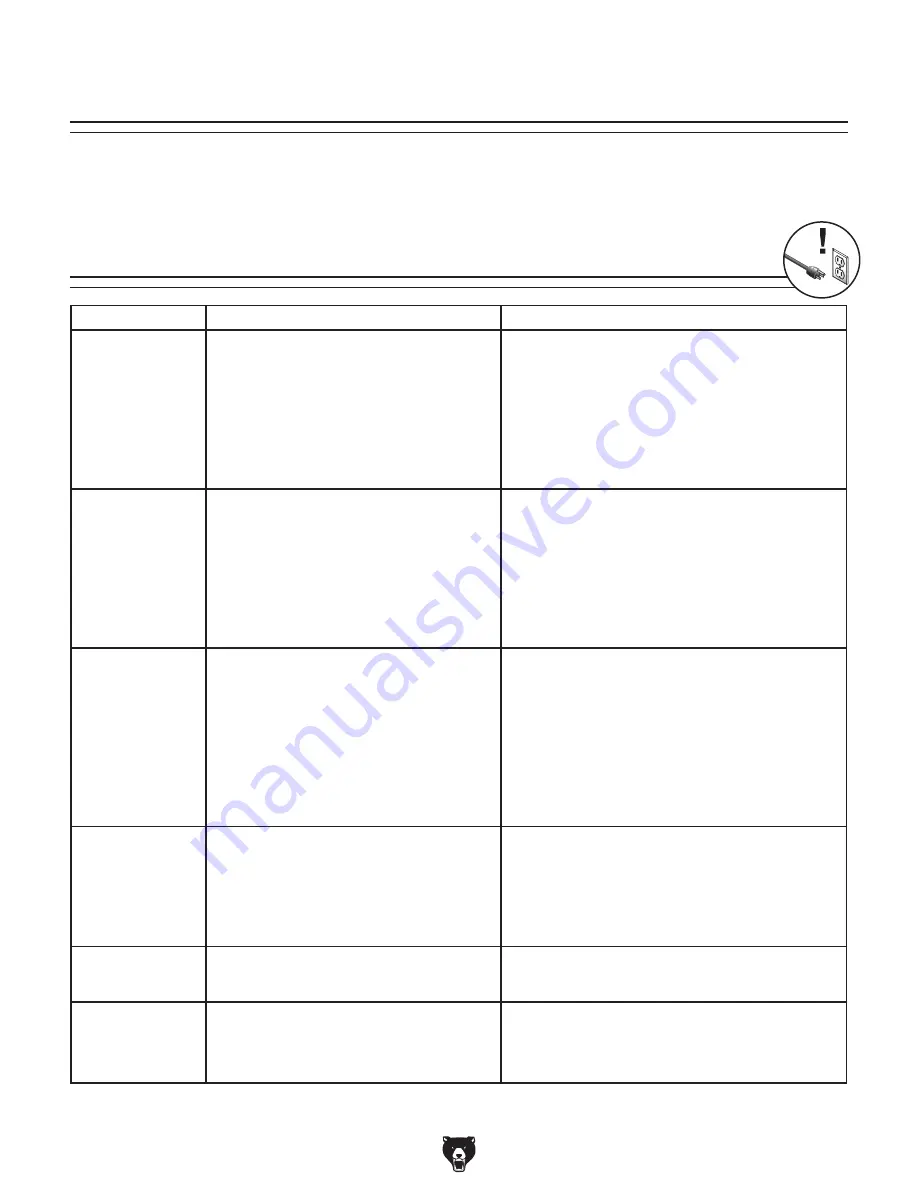

Symptom

Possible Cause

Possible Solution

Machine does not

start or a breaker

trips.

1. Power supply switched OFF or at fault.

2. Plug/receptacle at fault/wired wrong.

3. Motor connection wired wrong.

4. Wall circuit breaker tripped.

5. Wiring open/has high resistance.

6. Motor brushes at fault.

7. Motor ON/OFF switch at fault.

8. Motor at fault.

1. Ensure power supply is ON/has correct voltage.

2. Test for good contacts; correct the wiring.

3. Correct motor wiring connections (

Page 33).

4. Ensure circuit size is correct/replace weak breaker.

5. Check/fix broken, disconnected, or corroded wires.

6. Remove/replace brushes (

Page 31).

7. Replace switch.

8. Test/repair/replace.

Machine stalls or is

underpowered.

1. Drill bit not properly aligned with wheel.

2. Motor wired incorrectly.

3. Plug/receptacle at fault.

4. Motor brushes at fault.

5. Machine undersized for task.

6. Motor at fault.

7. Motor bearings at fault.

1. Properly align drill bit with wheel; make light

passes.

2. Wire motor correctly (

Page 33).

3. Test for good contacts/correct wiring.

4. Remove/replace brushes (

Page 31).

5. Use new grinding wheel; reduce the feed rate.

6. Test/repair/replace.

7. Test/repair/replace.

Machine has

vibration or noisy

operation.

1. Motor or component loose.

2. Grinding wheel at fault.

3. Incorrectly mounted to workbench.

4. Drill bit loose.

5. Motor bearings at fault.

6. Motor shaft bent.

1. Inspect/replace damaged bolts/nuts, and re-tighten

with thread locking fluid.

2. Dress/replace grinding wheel.

3. Adjust feet, shim, or tighten mounting hardware.

4. Properly mount the bit in the jig assembly; hold firmly

during operation.

5. Test by rotating shaft; rotational grinding/loose shaft

requires bearing replacement.

6. Test with dial indicator and replace motor.

Drill bit not

sharpened to

desired point angle.

1. Pivot base not set at the correct angle.

2. Drill bit not at the correct height.

3. Bit sharpened unevenly or more pressure

applied to one side than the other when

grinding.

1. Set the pivot base to the correct angle.

2. Use the jig assembly height scale to adjust the bit to

the proper height for its diameter.

3. Apply even pressure to both sides of the point when

grinding.

Drill bit smokes or

tip has black, blue,

or purple color.

1. Too much pressure applied.

1. Reduce pressure and feed rate, and discard the

damaged bit.

Wheel dulls or

clogs quickly, grit

falls off.

1. Too much pressure applied.

2 Bad wheel dress.

3. Wheel stored in moist or extreme

temperature environment.

1. Reduce pressure and feed rate.

2. Properly dress the wheel surfaces.

3. Replace wheel; store wheels in dry, moderate

temperature environment.

troubleshooting

Review the troubleshooting procedures in this section if a problem develops with your machine. If you need

replacement parts or additional help with a procedure, call our Technical Support.

Note: Please gather the

serial number and manufacture date of your machine before calling.

Содержание G0686

Страница 41: ......

Страница 44: ...REVISED ...