Page 20

SKU 65162

For technical questions, please call 1-800-444-3353.

For foam filter elements:

b.

Wash the element in warm water

and mild detergent several times.

Rinse. Squeeze out excess water

and allow it to dry completely. Soak

the filter in lightweight oil briefly, then

squeeze out the excess oil.

Install the new filter or the cleaned

4.

filter. Secure the Air Cleaner Cover

before use.

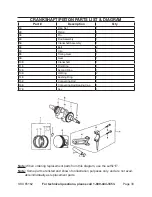

Spark Plug Maintenance

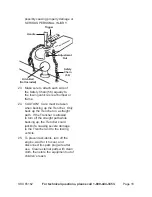

Disconnect spark plug wire from

1.

end of plug. Clean out debris from

around spark plug.

Using a spark plug wrench, remove

2.

the spark plug.

Inspect the spark plug:

3.

If the electrode is oily, clean it using a

clean, dry rag.

If the electrode has deposits on it,

polish it using emery paper.

If the white insulator is cracked or

chipped, the spark plug needs to be

replaced.

When installing a new spark

4.

plug, adjust the plug’s gap to the

specification on the Technical

specification chart. Do not pry

against the electrode, the spark plug

can be damaged.

Install the spark plug into the engine.

5.

Gasket-style: Finger-tighten until the

gasket contacts the cylinder head,

then turn about 1/2-2/3 more.

Non-gasket-style: Finger-tighten until

the plug contacts the head, then turn

about 1/16 more.

Apply dielectric spark plug boot

6.

protector (not included) to the end of

the spark plug and reattach the wire

securely.

Fuel Filter replacement (if equipped)

Warning!

riSk oF Fire

or exPLoSion.

Replace the

fuel filter in a well-ventilated

area away from ignition

sources. Do not smoke.

Wait for engine to cool before

1.

proceeding.

Wear protective gear including, ANSI-

2.

approved safety goggles, NIOSH-

approved dust mask/respirator, and

nitrile gloves.

Wipe Fuel Cap and top of Fuel Tank.

3.

Remove Fuel Filter (6R). Reattach

4.

Fuel Cap to prevent debris from

entering into Gas Tank.

Remove Buel Strainer. Wash with

5.

warm water and light detergent.

Flush and let dry.

Reinstall in the Gas Tank.

6.

cleaning, Maintenance, and

Lubrication Schedule

note:

This maintenance schedule

is intended solely as a general

guide. If performance decreases

or if equipment operates unusually,

check systems immediately. The

maintenance needs of each piece

of equipment will differ depending

on factors such as duty cycle,

temperature, air quality, fuel quality,

and other factors.

note:

These procedures are in addition to

the regular checks and maintenance

explained as part of the regular