FumeJet

®

Fume Exhaust Fans

7

®

Move the fan to the desired location. Check and tighten

fasteners throughout the unit and then fasten securely

through mounting holes provided in the base angles.

The unit must be set level (shimming may be necessary).

Flexible duct connections and vibration isolators should

be used where noise is a factor.

The motor voltage and ampere rating must be checked

for compatibility with the electrical supply prior to final

electrical connection. Supply wiring to the fan must

be properly fused, and conform to local and national

electrical codes.

IMPORTANT

When installing a fan, ensure the proper protective

devices are used to protect personnel from moving

parts and other hazards.

Electrical Disconnects

All fan motors should have disconnects located in

close visual proximity to turn off electrical service.

Service disconnects shall be locked out when

maintenance is being performed.

Moving Parts

All moving parts must have guards to protect

personnel. Refer to local codes for requirements as to

the number, type and design. Fully secure fan wheel

before performing any maintenance. The fan wheel

may start “free wheeling” even if all electrical power

has been disconnected. Before the initial start-up

or any restart, check the guards (motor cover and

weatherhood) and check the access doors to ensure

that they are installed and secure.

Installation

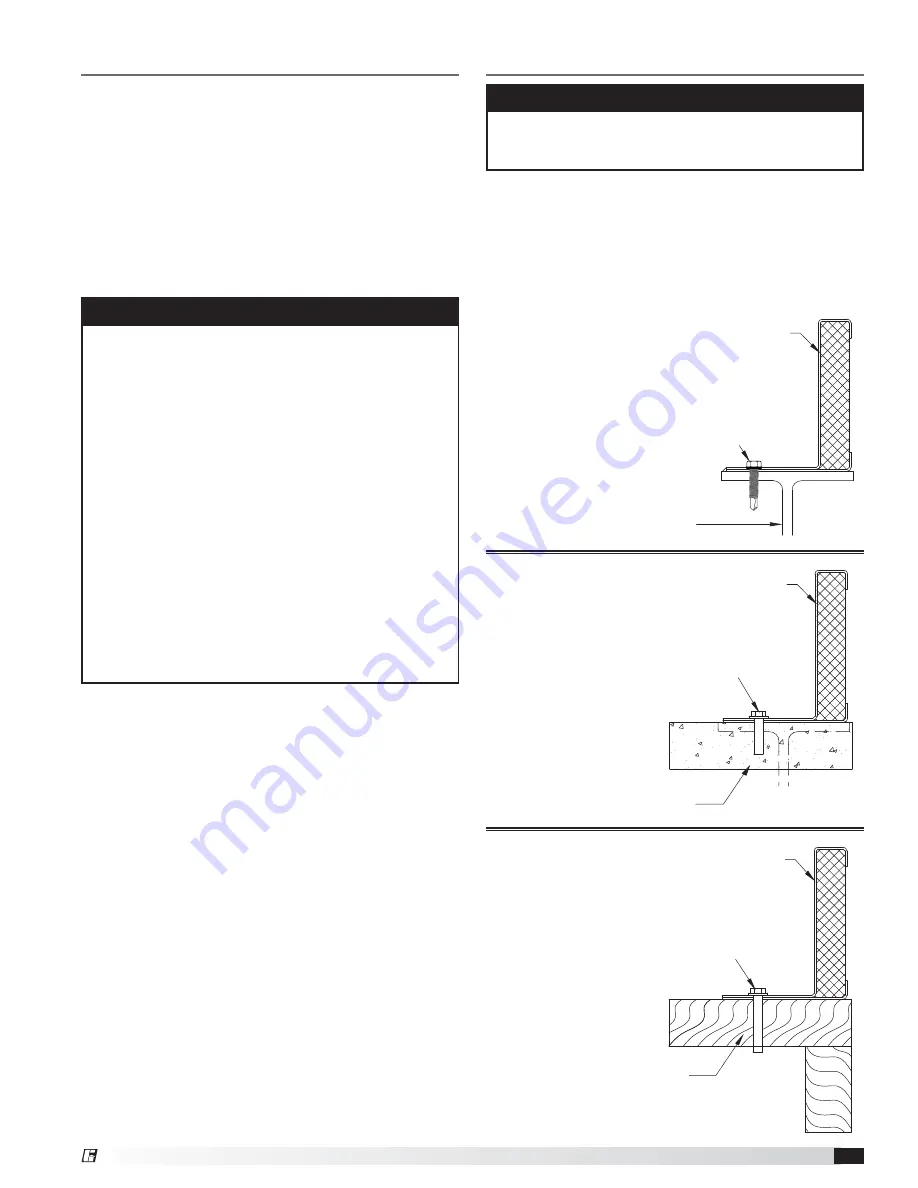

Roof Curb and Mounting Details

Required with curb cap inlet box or mega stack.

The

figures below illustrate three common methods used

to install roof curbs for FumeJet

®

systems. Methods

used to attach a unit are dependent on local codes, roof

construction design and roof construction materials.

Consult an architect or structural engineer for proper

means of attachment.

NOTE

Steel, concrete or wood roof support is per structural

engineer and in accordance with load requirements

and applicable building codes.

Steel

STEEL STRUCTURAL SUPPORT

(BY OTHERS, SEE NOTE ABOVE)

Continuous weld or stitch weld.

Minimum 6 inch

(152.4 mm)

stitch weld by

3.25 inch

(82.5 mm)

spacing minimum.

Minimum 6 inch

(152.4 mm)

weld on each corner.

OR

Install 5/16 inch

(7.9375 mm)

24 Dril-Flex® Self-Drilling

Tapping Screws. 3/16 inch

(4.7625 mm)

minimum thread

engagement into A36 steel, centered in flange.

4.5 inch

(114.3 mm)

spacing

5/8 inch

(15.875 mm)

minimum edge distance

ALL HARDWARE BY OTHERS

Greenheck Roof Curb GPFHL

Concrete

CONCRETE STRUCTURAL SUPPORT

(BY OTHERS, SEE NOTE ABOVE)

Install 3/8 inch

(9.525 mm)

SS power wedge bolts

2.5 inch

(63.5 mm)

maximum spacing from curb corners

4.5 inch

(114.3 mm)

maximum bolt spacing

3.5 inch

(88.9 mm)

minimum embedment

4.5 inch

(114.3 mm)

minimum edge

distance centered in flange

ALL HARDWARE BY OTHERS

Greenheck Roof Curb GPFHL

Wood

WOODEN STRUCTURAL SUPPORT

(BY OTHERS, SEE NOTE ABOVE)

Greenheck Roof Curb GPFHL

Install 3/8 inch

(9.525 mm)

SS lag or thru-bolt with

1 inch

(25.4 mm)

O.D. washer

2.5 inch

(63.5 mm)

maximum spacing from curb corners

4.5 inch

(114.3 mm)

maximum bolt spacing

3.5 inch

(88.9 mm)

minimum tread engagement,

not including tapered tip

2 inch

(50.8 mm)

minimum edge distance,

centered in flange

Pre-drill holes 40-60% of lag diameter

ALL HARDWARE BY OTHERS