Centrifugal Inline Fans

10

®

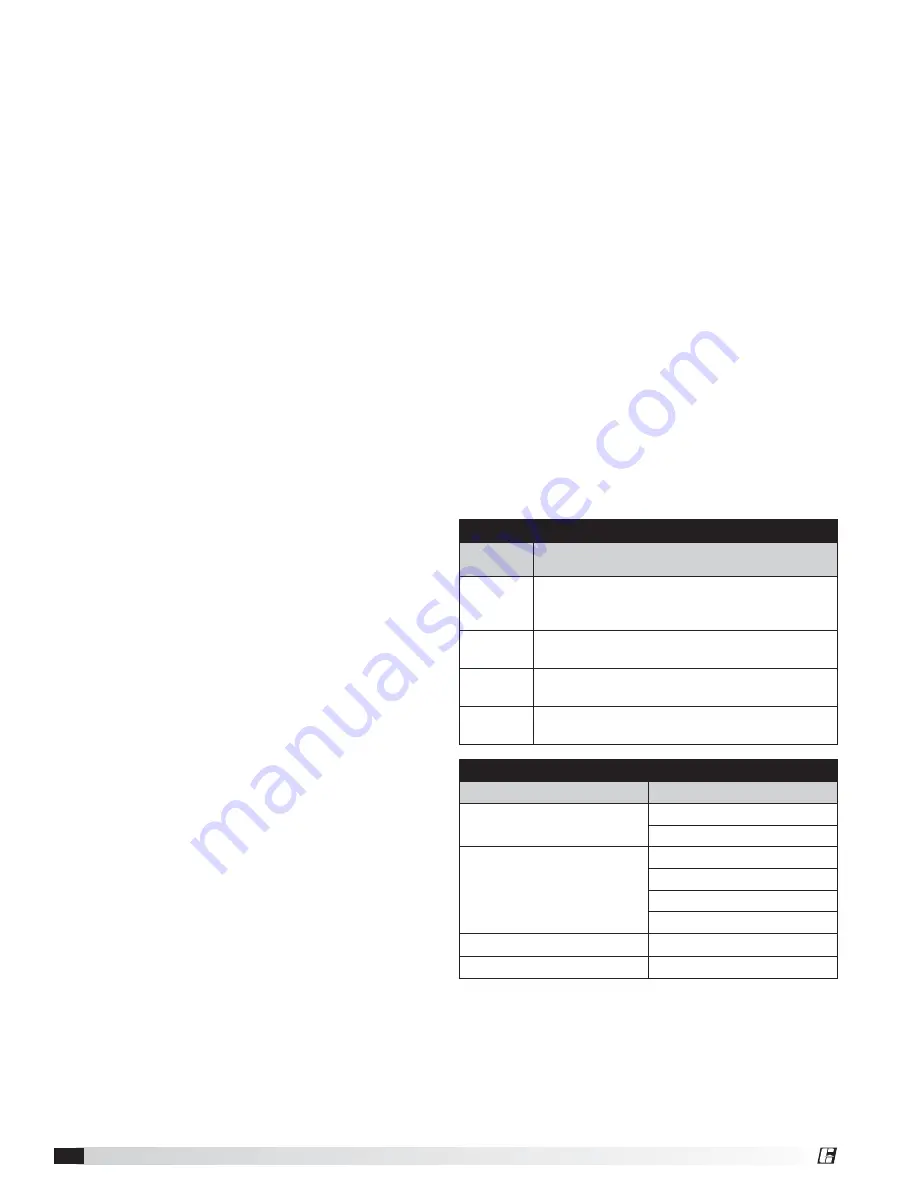

Grease Manufacturers

Manufacturer

Grease (NLGI #2)

Chevron U.S.A. Inc

Chevron SRI Grease 2

Chevron Multifak EP 2

Exxon Mobil

Mobilux EP 2

Mobilith SHC 220

Mobilith AW-2

Unirex N2

BP Amoco

Rykon Premium #2 EP

Shell

Shell Gadus S2 V220 2

Suggested Fan Bearing Greasing Intervals

Interval

(months)

Type of Service

1 to 3

Heavy duty in dirty, dusty locations; high

ambient temperatures; moisture laden

atmosphere; vibration.

3 to 6

12 to 24 hours per day, heavy duty, or if

moisture is present

6 to 12

8 to 16 hours per day in clean, relatively dry

atmosphere

12 to 18

Infrequent operation or light duty in clean

atmosphere

5. Shaft bearings can be classified in two groups:

relubricating and non-relubricating. All bearings

on standard belt drive fans are factory lubricated

and require no further lubrication under normal use

(between -20ºF and 180ºF

(-29

º

C and 82ºC)

in a

relatively clean environment).

6. Units installed in hot, humid or dirty locations should

be equipped with special bearings. These bearings

will require frequent lubrication. Caution should be

employed to prevent overpacking or contamination.

7. Grease fittings should be wiped clean. The unit

should be in operation while lubricating. Extreme

care should be used around moving parts.

8. Grease should be pumped in very slowly until a slight

bead forms around the seal. A high grade lithium

base grease should be used.

Recommended Relubrication Frequency

in Months

NOTE: If unusual environment conditions exist (extreme

temperature, moisture or contaminants) more frequent

lubrication is required.

A good quality lithium base grease, conforming to

NLGI Grade 2 consistency, such as those listed here

may be used with fan bearings.

3.

Standard Mounting:

Take the two socket head cap

screws that were removed and install them into the

visibly threaded holes on the wheel hub.

Reverse Mounting:

Install the two socket head cap

screws into the visibly threaded holes of the bushing

flange.

4. Once both socket head cap screws are installed,

tighten them an eighth of a turn at a time, alternating

between the two until the hub comes loose from the

bushing.

Bushing Installation

1. Clean all surfaces of hub and bushing to remove any

oil or residue present and do not use any lubricant to

install bushing into the hub. For both standard and

reverse mounting styles, the socket head cap screws

are adjustable from the inlet of the fan.

2.

Standard Mounting:

Slide the bushing and shaft

key onto the fan shaft followed by the wheel and hub

assembly. If present, use the keyway setscrew to

hold the shaft key and bushing in place but DO NOT

overtighten as this can damage the bushing. Align

the unthreaded holes of the hub with the threaded

holes of the tapered bushing.

Reverse Mounting:

Slide the wheel and hub

assembly onto the fans shaft followed by the bushing

and shaft key. If present, use the keyway setscrew to

hold the shaft key and bushing in place but DO NOT

overtighten as this can damage the bushing. Align

the unthreaded holes of the tapered bushing with the

threaded holes of the hub.

3. Install the two bushing socket head cap screws

into the aligned holes by hand (or without excessive

torque) until the heads of the socket head cap

screws are seated against the mating surface.

4. Adjust the height of the wheel in the fan relative to

the inlet venturi then tighten the two socket head

cap screws an eighth turn at a time in an alternating

fashion and to a torque of 10 ft-lbs.

Belt/Bearing Maintenance - Belt Drive

1. Belts tend to stretch after a period of time. They

should be checked periodically for wear and

tightness. When replacing belts, use the same type

as supplied with the unit.

2. Matched belts should always be used on units with

multi-groove pulleys.

3. For belt replacement, loosen the tensioning device

enough to allow removal of the belt by hand. Do not

force belts on or off. This may cause cords to break,

leading to premature belt failure.

4. Once installed, adjust belts as shown in

Pre-Start-Up Checks.