Please contact technical support if it is necessary to power

additional sensors beyond the numbers listed above. These

figures do not account for additional devices such as Digita

®

Switches being used. If using a combination of devices, please

contact technical support for exact details on how many devices

the logic panel can power.

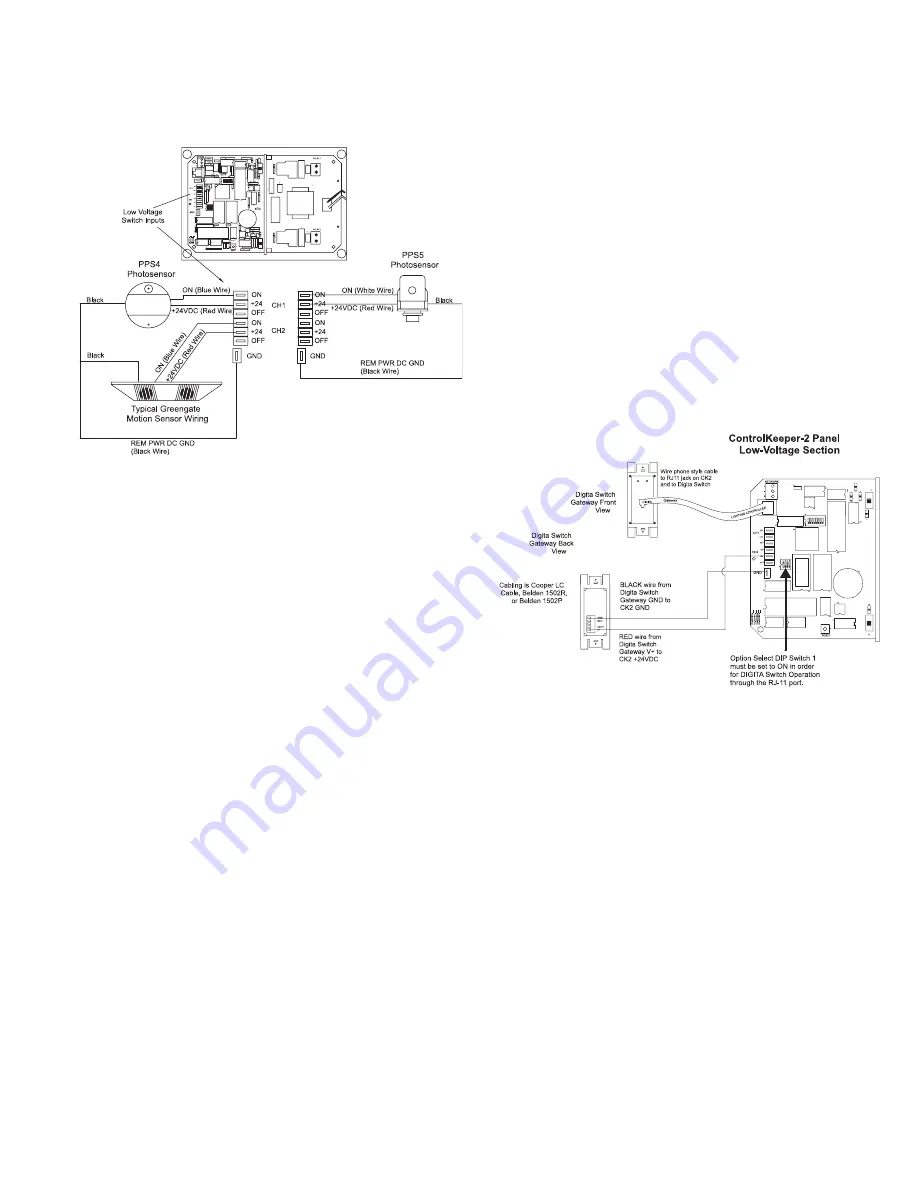

Photosensor and Motion Sensor Wiring

Digita

®

Switch Wiring

Each ControlKeeper-2

®

panel is capable of supporting up to 14

Digita

®

Switch device stations and 1 Digita

®

Switch Gateway (the

number the controller is able to support is dependent on the num

-

ber of other low voltage devices wired that require power from our

logic board. Please contact Technical Support for exact details of

how many devices your logic board can power.)

Digita

®

Switch cable type should be Cooper LC Cable, Belden

1502R (non-plenum), or Belden 1502P (plenum).

For best network performance, one of the suggested cables

should be used. If the specified cable is not used and com

-

munications problems occur that require troubleshooting as

-

sistance, additional charges for support may be assessed.

Digita

®

Switches do not wire directly to the ControlKeeper-2

®

panel, but are wired to a CAN Bus network that connects to the

ControlKeeper-2

®

through a Digita

®

Switch Gateway. Digita

®

Switch devices should be networked together in a daisy chain

configuration. No T-Taps/Stars should be used. The Digita

®

Switch Gateway device should reside somewhere within the

daisy chain switch network. Total daisy chain network length

should not exceed 1000 feet.

The following instructions describe the Digita

®

Switch Gateway

connection to the ControlKeeper-2

®

. Please refer to the Digita

®

Switch Installation Instructions included with your Digita

®

Switch

Gateway for information on wiring the Digita

®

Switch network

to the Digita

®

Switch Gateway.

1. Mount the Digita

®

Switch Gateway next to the ControlKeep-

er-2

®

panel. A six foot phone style cable has been provided

for connection to the ControlKeeper-2

®

panel.

2. Run a length of the Digita

®

Switch LC or Belden cabling

from the Digita

®

Switch Gateway location to the low voltage

section of the ControlKeeper-2

®

.

3. Connect the RED wire in the cable to the +V terminal on the

back of the Digita

®

Switch Gateway and to the Control

Keeper-2

®

at one of the switch input +24VDC terminals.

4. Connect the BLACK wire in the cable to the GND terminal

on the back of the Digita

®

Switch Gateway and to the Con-

trolKeeper-2

®

remote power connector GND terminal.

5. Tape back or cap the blue and white wires and shield wire

for the cable. They will not be used for connection between

the Digita

®

Switch Gateway and lighting controller.

6. Locate the 6 foot phone style cable included in the Digita

®

Switch Gateway box. Run this from the Digita

®

Switch

Gateway into the low voltage section of the ControlKeeper-2

®

enclosure plugging the end that is labeled DIGITA into the

Digita

®

Switch Gateway. Plug the end that is labeled LIGHT

ING CONTROLLER into the ControlKeeper-2

®

RJ connec-

tor.

7. Ensure that the ControlKeeper-2

®

Option Select dipswitch 1

is in the on position to configure the ControlKeeper-2

®

to

accept the Digita

®

commands through its COM port.

Digita

®

Switch Wiring

Network Wiring Notes

The ControlKeeper-2

®

is designed to communicate with other

ControlKeeper network panels using a lighting control RS-485

network for communications. This allows the panels to share

information back and forth as well as allows the system to be

programmed from one central location by a computer with the

Keeper Enterprise Software.

Page 3