16

❏

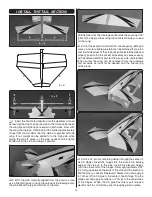

14. Make 6" [152mm] battery straps by cutting pieces

from the included non-adhesive hook and loop material and

overlapping the mating ends by 1" [25.4mm]. Feed the straps

through the slots shown in the photo.

Glow Engine

The following section only contains information relevant

to installing a glow engine. If you have already installed a

brushless motor then skip this section. The O.S. .65 AX engine

is shown in this section with the stock muffl er. Other model

engines will install in a similar manner. If your throttle arm is

in a different position than what is shown in the photos then

you will need to adjust the location of the throttle pushrod

accordingly.

This section shows the stock muffl er being used and therefore

the angled engine mount pattern was chosen to align the

muffl er in the cavity on the bottom of the fuselage. If you plan

to use a 4-stroke engine or a Pitts style muffl er, then you can

use the engine mount pattern that has the center lines running

horizontally and vertically depending on the engine model. A

.55AX O.S. engine stock muffl er will fi t in the cavity without

the need to cut away the bottom of the cowl. The .65AX stock

muffl er will also fi t in the cavity; however, the majority of the

bottom of the cowl will need to be cut away because the

muffl er will protrude slightly lower than the bottom line of the

fuselage. The .65AX can also be mounted inverted with the

muffl er located on the side of the fuselage (not shown). Choose

the engine orientation that works for you before proceeding.

❏

1. If you are mounting a .55AX or .65AX engine in the

angled orientation, drill a hole for the throttle pushrod in the

fi rewall in the location shown using an 11/64" [4.4 mm] drill bit.

If you are installing a different engine or an inverted engine,

you will need to locate this hole according to the position of

the throttle arm on your carburetor. Be sure you are clearing

the fuel tank area when drilling the hole.

❏

2. Glue the fuel tank support in place. Be sure the notch

for the throttle pushrod tube aligns with the hole you drilled

in the previous step.

❏

3. Cut the included outer pushrod tube to 9" [ 229 mm].