12

❏

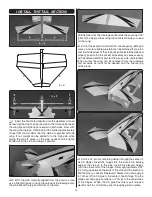

9. Locate the mounting blocks under the covering in the

elevator halves for the elevator control horns. Position a

control horn onto each elevator half over these mounting

blocks and mark the locations for the control horn mounting

screws. Drill 5/64" [2mm] holes at your marks. Install the

control horns using four 2-56 x 5/8" [16mm] machine screws

and control horn backplates.

❏

10. The procedure for making the elevator pushrods is

the same as it was for the ailerons. A 5-5/16" [135mm] and a

7-1/16" [180mm] carbon tube are included for strengthening

the elevator pushrods. The clevises should be connected to

the fourth outer holes from the control horn bases. Assemble

and install the rudder pushrod in the same manner using the

remaining 5-7/8" [150mm] carbon tube.

❏

11. Apply a drop or two of oil onto the tail wheel axle and

slide on the tail wheel. Secure it in place with a 1/8" [3.2mm]

wheel collar and 4-40 set screw. Confi rm that the tail wheel

rotates freely.

INSTALL THE MAIN LANDING GEAR

❏

1. Install the axles onto the main landing gear legs using

the large axle nuts. Orient them so the fl at spots at the ends

of the axles are facing downward.

❏

2. Slide a 5/32" [4mm] wheel collar onto the axle and

tighten it against the base of the axle using a 6-32 x 1/4"

[6mm] socket head cap screw and thread locking compound.

Apply a drop or two of oil to the axle and then install a main

wheel. Install another 5/32" [4mm] wheel collar and 6-32 x 1/4"

[6mm] SHCS onto the axle against the fl at spot. Confi rm that

the wheel rotates freely. Repeat this step for the other axle.