❏

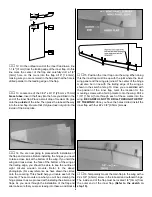

8. Drill a 5/32" [4mm] hole in the leading edge of the

elevator 1/2" [13mm] deep at the 1" [25mm] mark.

❏

9. Locate the tail wheel wire and install it into the hole

you just drilled. On the leading edge of the rudder, cut a slot

the width of the nylon bearing. Remove the tail wheel wire

and cut the slot to a depth that allows the bearing to rest in

the leading edge of the rudder. Fuelproof the slot with a thin

coat of 6-minute epoxy. After the epoxy cures, re-install the

tail wheel wire into the rudder.

❏

10. Hold the rudder up to the fin. Mark the location of the

nylon bearing from the tail wheel wire.

❏

11. Cut a slot in the end of the fuselage from the mark you

made to the bottom of the fuselage. Insert the nylon bearing

into the slot. When you are satisfied with the fit, glue the

nylon bearing to the fuselage with 6-minute epoxy. Apply a

light coat of petroleum jelly to the wire and the nylon bearing

to prevent glue from getting into the nylon bearing.

❏

12. Install the hinges into the rudder using the same

procedure used for the elevator. Slide the hinges into the fin,

making sure that the tail wheel wire is inserted into the hole

you drilled in the leading edge of the rudder. When you are

satisfied with the fit of the rudder to the fin, apply 6 drops of

thin CA glue to each of the hinges.

❏

13. Install the tail wheel onto the tail wheel wire. Hold it in

place with the 3/32" wheel collar and the 4-40 set screw.

15