8

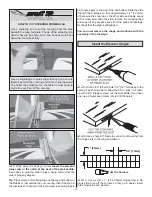

HINGE LINE

CORRECT

INCORRECT

❏ ❏

6. Cut the control horn and mounting plate apart. Attach

the clevis in the outer hole of a nylon control horn. Place the

control horn in line with the hole 3/4" [19mm] from the center

of the servo arm. When positioned properly the control horn

will rest on a hardwood plate in the aileron. Mark the location

of the mounting holes onto the aileron. Drill a 3/32" [2.4mm]

hole on the marks, drilling through the plywood plate and the

top of the aileron.

❏ ❏

7. Insert two 2-56 x 5/8" [16mm] machine screws

through the control horn and aileron. Secure the control horn

to the aileron with the nylon control horn backplate.

❏ ❏

8. Slide a silicone clevis retainer over the clevis. With

the aileron servo and the aileron centered, mark the aileron

pushrod where it crosses the aileron servo arm. Make a 90°

bend at the mark. Cut the pushrod 3/8" [9.5mm] past the

bend. Attach the pushrod to the aileron servo arm with a

nylon FasLink.

❏ ❏

9. Glue the carbon fi ber anti rotation pin in the hole as

shown. The pin should protrude approximately 1/4" [6.4mm].

❏

10. Repeat steps 1 to 9 for the left wing panel.

ASSEMBLE THE FUSELAGE

Install the Main Landing Gear

❏ ❏

1. Insert a 4mm axle through the right main landing

gear. Secure the axle to the landing gear with a 5mm fl at

washer and 5mm lock nut. Note: The front of the main

landing gear sweeps forward.

❏ ❏

2. Install two 5mm fl at washers on the axle, then the

foam main wheel, followed by a 4.2mm wheel collar. Secure

the wheel collar on the axle with 6-32 set screw. Mark the

8