Expert 24 user manual

Trouble Shooting

5-2

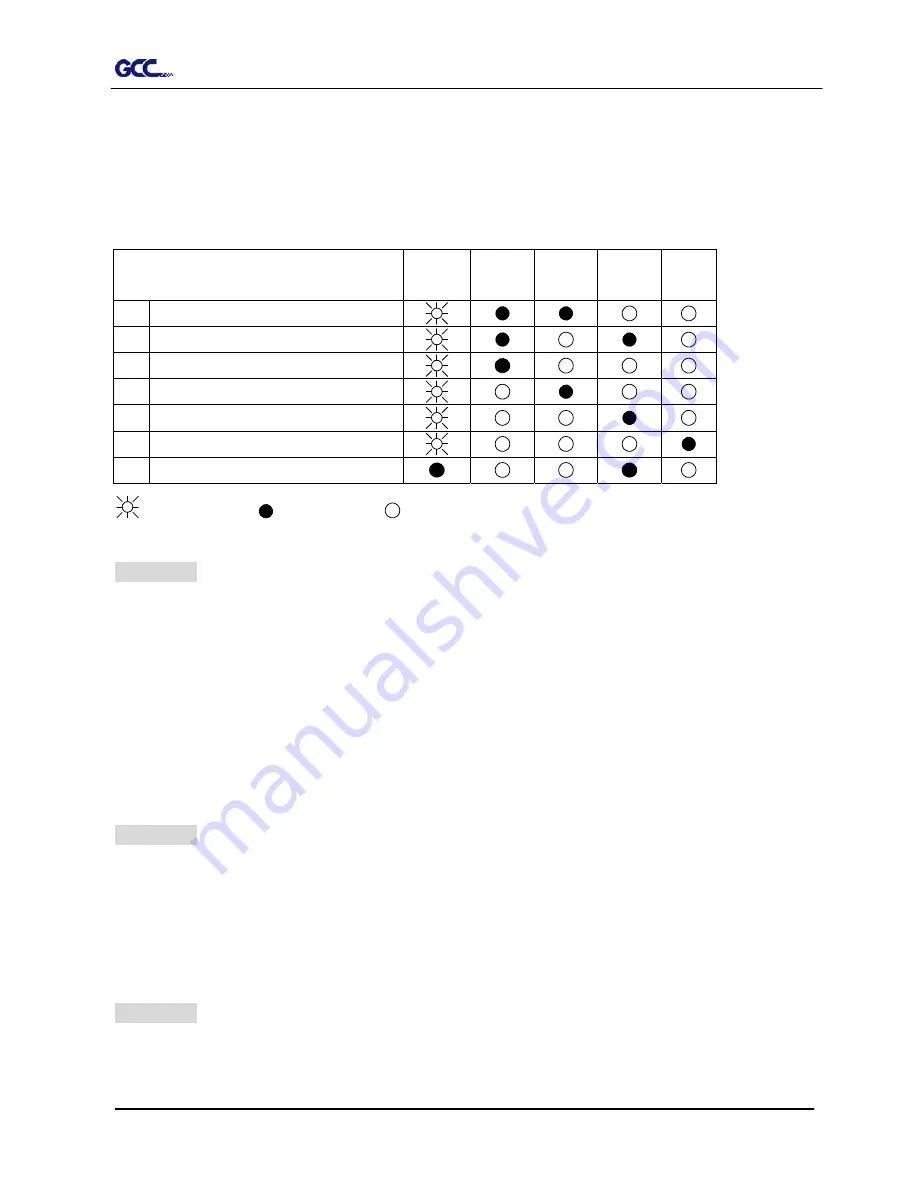

5.2.1 Warning Indicators

When the ERROR LED flashes (as shown below), take the necessary actions according to

the following instructions. When the problems are solved, the ERROR LED will turn off

automatically. Pressing the ON/OFF LINE button can also turn off the ERROR LED.

Warning Indicators

ERROR

ON/OFF

LINE

REPEAT

DATA

CLEAR

CUT

TEST

1

Graph was clipped

2

HPGL/2 command Error

3

Lever up or no media

4 Cannot

repeat

5 Communication

error

6

Width sensor error

7

Check media, drum or X motor

= flash

= on

= off

Warning 1

The graph is clipped

This condition indicates that the cutting graph is bigger than the cutting area.

You can solve the problem by:

1. Reload a wider or longer media.

2. Move the pinch rollers to widen the cutting area.

3. Re-scale the graph to a smaller size. Then send the cutting job again from your computer

to the cutting plotter.

Warning

2

HPGL/2 command error

If the cutting plotter cannot recognize the commands from your computer, please check the

commands applied to your cutting plotter in the HP-GL/2 or HPGL commands. Then send the

same job to the cutting plotter again.

If that doesn’t solve the problem, please contact your local dealer.

Warning 3

Lever up or no media

Check that you have lowered the lever down and make sure that you load the media before

cutting.

Содержание Expert 24

Страница 1: ...EXPERT 24 CUTTING PLOTTER User Manual Great Computer Corporation...

Страница 33: ...Expert 24 user manual Trouble Shooting 5 8 6 Finish 7 Choose Install the software automatically Recommended...

Страница 34: ...Expert 24 user manual Trouble Shooting 5 9 8 Wait a few minutes 9 Now you can drive GCC cutter...