440 04 7113 02

19

Specifications subject to change without notice.

FIRE OR EXPLOSION HAZARD

Failure to follow this warning could result in personal

injury, death, and/or property damage.

Never purge a gas line into a combustion chamber.

Never test for gas leaks with an open flame. Use a

commercially

available

soap

solution

made

specifically for the detection of leaks to check all

connections. A fire or explosion may result causing

property damage, personal injury or loss of life.

!

WARNING

14. Check for gas leaks with a commercially available

soap solution made specifically for the detection of

leaks.

15. Turn gas on at electric switch on gas valve and at

external shut-off or meter

16. Turn power on at external disconnect, fuse or circuit

breaker.

17. Run the furnace through two complete heating cycles

to check for proper operation

18. Install control door when complete.

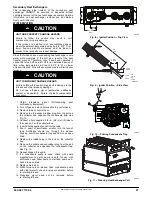

Servicing Hot Surface Igniter

The igniter does

NOT

require annual inspection. Check

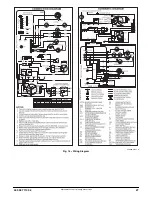

igniter resistance before removal. Refer to Fig. 8, 9 and 14.

1. Turn off gas and electrical supplies to furnace.

2. Remove control door.

3. Disconnect igniter wire connection.

4. Check igniter resistance. Igniter resistance is affected

by temperature. Only check resistance when the

igniter is at room temperature.

a. Using an ohm meter, check resistance across both

igniter leads in connector.

b. Cold reading should be between 40 ohms and 70

ohms.

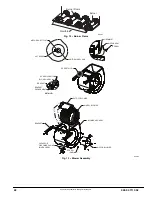

5. Remove igniter assembly.

a. Using a 1/4--in. driver, remove the two screws

securing the igniter mounting bracket to the burner

assembly (See Fig. 14 .)

b. Carefully withdraw the igniter and bracket assembly

through the front of the burner assembly without

striking the igniter on surrounding parts.

c. Inspect igniter for signs of damage or failure.

d. If replacement is required, remove the screw that

secures the igniter on igniter bracket and remove the

igniter.

6. To replace igniter and bracket assembly, reverse

items 5a through 5d.

7. Reconnect igniter harness to the igniter, dressing the

igniter wires to ensure there is no tension on the

igniter itself. (See Fig. 14.)

8. Turn on gas and electrical supplies to furnace.

9. Verify igniter operation by initiating control board self--

test feature or by cycling thermostat.

10. Replace control door.

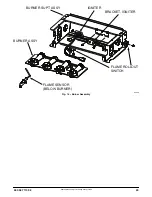

Flushing Collector Box and Drainage System

ELECTRICAL SHOCK AND FIRE HAZARD

Failure to follow this warning could result in personal

injury, death, and/or property damage.

Turn off the gas and electrical supplies to the furnace

and install lockout tag before performing any

maintenance or service. Follow the operating

instructions on the label attached to the furnace.

!

WARNING

1. Turn off gas and electrical supplies to furnace.

2. Remove control door.

3. Disconnect pressure switch tube from pressure

switch port.

NOTE

: Ensure the pressure switch tube disconnected from

the pressure switch is higher than the collector box opening

or water will flow out of tube.

4. Remove the collector box plug from the top port on

the upper corner of the collector box. (See Fig. 10)

5. Attach a funnel with a flexible tube to port on the

collector box.

6. Flush inside of collector box with water until discharge

water from condensate trap is clean and runs freely.

7. Repeat steps 4 thru 6 with middle plug on upper

corner of collector box.

8. Remove the pressure switch tube from the collector

box.

NOTE

: Do

NOT

blow into tube with tube connected to the

pressure switch.

9. Clean pressure switch port on collect box with a small

wire. Shake any water out of pressure switch tube.

10. Reconnect tube to pressure switch and pressure

switch port.

11. Remove the relief tube from the port on the collector

box and the trap.

12. Clean the relief port on collect box and the trap with a

small wire. Shake any water out of the tube.

13. Reconnect relief tube to trap and collector box ports.

Cleaning Condensate Drain and Trap

NOTE

: If the condensate trap is removed, a new gasket

between the trap and collector box is required. Verify a

condensate trap gasket is included in the service kit or

obtain one from your local distributor.

1. Disconnect power at external disconnect, fuse or

circuit breaker.

2. Turn off gas at external shut-off or gas meter.

3. Remove control door and set aside.

4. Turn electric switch on gas valve to OFF.

5. Disconnect external drain from condensate drain

elbow or drain extension pipe inside the furnace and

set aside.

6. Disconnect the condensate trap relief hose from

collector box port and condensate trap.

NOTE

: If condensate has a heat pad attached to the trap,

trace the wires for the pad back to the connection point and

disconnect the wires for the heat pad.

7. Remove the screw that secures the condensate trap

to the collector box, remove the trap and set aside.

8. Remove the trap gasket from the collector box if it did

not come off when the trap was removed.

9. Discard the old trap gasket.

10. Rinse condensate trap in warm water until trap is

clean.