14

440 04 7113 02

Specifications subject to change without notice.

SERVICE AND MAINTENANCE

PROCEDURES

Untrained personnel can perform basic maintenance func-

tions such as cleaning and replacing air filters. All other opera-

tions must be performed by trained service personnel. A quali-

fied service person should inspect the furnace once a year.

FIRE, INJURY OR DEATH HAZARD

Failure to follow this warning could result in personal

injury, death and/or property damage.

The ability to properly perform maintenance on this

equipment requires certain knowledge, mechanical

skills, tools, and equipment. If you do not possess

these, do not attempt to perform any service and

maintenance on this equipment other than those

procedures recommended in the Owner’s Manual.

!

WARNING

ENVIRONMENTAL HAZARD

Failure to follow this caution may result in

environmental pollution.

Remove and recycle all components or materials (i.e.

oil, refrigerant, control board, etc.) before unit final

disposal.

CAUTION

!

ELECTRICAL SHOCK, FIRE OR EXPLOSION

HAZARD

Failure to follow this warning could result in personal

injury or death, or property damage.

Before installing, modifying, or servicing system, main

electrical disconnect switch must be in the OFF

position and install a lockout tag. There may be more

than one disconnect switch. Lock out and tag switch

with a suitable warning label. Verify proper operation

after servicing.

!

WARNING

ELECTRICAL OPERATION HAZARD

Failure to follow this caution may result in improper

furnace operation or failure of furnace.

Label all wires prior to disconnection when servicing

controls. Wiring errors can cause improper and

dangerous operation.

CAUTION

!

General

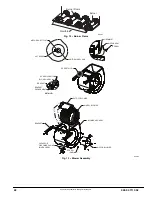

These instructions are written as if the furnace is installed in

an upflow application. An upflow furnace application is

where the blower is located below the combustion and

controls section of the furnace, and conditioned air is

discharged upward. Since this furnace can be installed in

any of the 4 positions shown in Fig. 6, you must revise your

orientation to component location accordingly.

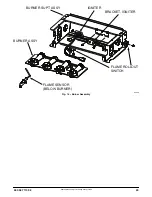

Electrical Controls and Wiring

Pressure Switches

Each pressure switch is labeled with the reference location

(noted as “COLLECTOR BOX--LPS” or “HOUSING--HPS”

ON THE SWITCH). The nominal break point of each switch

is shown on the label below the reference location in inches

of water column, “W.C.” The maximum and minimum break

point of the switch is +/-- 0.05 inches of water column from

the nominal break point of the switch. The maximum make

point of the switch is 0.10 inches of water above the

maximum break point of the switch

Example:

Nominal break point on pressure switch is

0.68--in. W.C. The minimum break point of the switch is

0.63--in. W.C. The maximum break point of the switch is

0.73--in. W.C. The maximum make point of the switch is

0.83--in. W.C.

ELECTRICAL SHOCK HAZARD

Failure to follow this warning could result in personal

injury or death.

There may be more than one electrical supply to the

furnace. Check accessories and cooling unit for

additional electrical supplies that must be shut off

during furnace servicing. Lock out and tag switch with

a suitable warning label.

!

WARNING

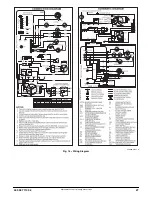

The electrical ground and polarity for 115--v wiring must be

properly maintained. Refer to Fig. 7 for field wiring

information and to Fig. 16 for furnace wiring information.

NOTE

: If the polarity is not correct, the STATUS LED on the

control will flash rapidly and prevent the furnace from

heating. The control system also requires an earth ground

for proper operation of the control and flame--sensing

electrode.

The 24--v circuit contains an automotive--type, 3--amp. fuse

located on the control. (See Fig. 2.) Any shorts of the 24--v

wiring during installation, service, or maintenance will cause

this fuse to blow. If fuse replacement is required, use ONLY

a 3--amp. fuse. The control LED will display status code 24

when fuse needs to be replaced.

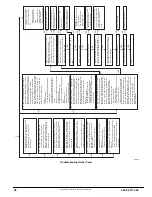

Troubleshooting

Refer to the service label. (See Fig. 5—Service Label.)

The Troubleshooting Guide (See Fig. 15) can be a useful

tool in isolating furnace operation problems. Beginning with

the word “Start,” answer each question and follow the

appropriate arrow to the next item.

The Guide will help to identify the problem or failed

component. After replacing any component, verify correct

operation sequence.

Proper instrumentation is required to service electrical

controls. The control in this furnace is equipped with a

Status Code LED (Light--Emitting Diode) to aid in

installation, servicing, and troubleshooting. Status codes

can be viewed at the indicator in blower door. The amber

furnace control LED is either ON continuously, rapid

flashing, or a code composed of 2 digits. The first digit is the

number of short flashes, the second digit is the number of

long flashes.

For an explanation of status codes, refer to service label

located on control door or Fig. 5, and the troubleshooting

guide which can be obtained from your distributor.

Retrieving Stored Fault Codes

NOTE

: Fault codes cannot be retrieved if a thermostat

signal (24-v on W, Y, G, etc.) is present, or if any delays

such as blower off-delays are active.

The stored status codes will NOT be erased from the control

memory when 115- or 24-v power is interrupted. See the

Service Label (Fig. 5) for more information. The most recent

fault code may be retrieved as follows:

1. Leave 115-v power connected to furnace.

2. Observe the status LED through the blower door (the

lower door on upflow applications) indicator. Refer to

the Service Label (Fig. 5) to interpret the LED.

3. Remove the Main/Control door (the upper door on

upflow installations).

4. BRIEFLY (2--3 seconds) disconnect and reconnect

ONE of the main limit wires.

5. The LED will flash the last stored fault code. Refer to

the Service Label (Fig. 5) to interpret the LED.

6. A component test sequence will follow.

7. Reinstall the Main/Control door.