Operation

10

311320K

Operation

Grounding

Check your local electrical code and proportioner

manual for detailed grounding instructions.

Spray gun / Dispense valve:

ground through

connection to a properly grounded fluid hose and pump.

Coupling Block

Install Coupling Block

1. Inspect coupling block gaskets for damage and

wear. Replace if necessary.

2. With gaskets in place, fit coupling block to gun

block.

3. Insert coupling block mounting screw and tighten

securely with 5/16 in. nut driver.

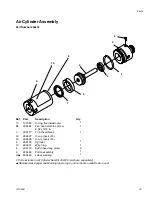

Manual Valves

NOTE:

Triggering gun with manual valves closed may

cause crossover if gun ports contain residual chemical.

1. Open manual valves using 5/16 in. nut driver; turn

manual valves counterclockwise approximately

three full turns. Do not open until it bottoms out.

2. Close manual valves by turning fully clockwise.

Remove Coupling Block

1. Disconnect air hose.

2. Close both manual valves.

3. Remove coupling block mounting screw (F

4. Separate coupling block from gun. Do not lose

gaskets.

5. Use gun cleaner to wipe clean mating surface of

gun block and coupling block. Cover exposed

opening with grease.

To prevent accidental gun operation, always

disconnect air supply before servicing gun or anytime

gun is not in use.

The equipment must be grounded to reduce the risk

of static sparking. Static sparking can cause fumes to

ignite or explode. Grounding provides an escape wire

for the electric current.

F

IG

. 3 Coupling Block

Coupling Block

Gaskets

Coupling Block

Mounting Screw

Never open manual valves unless coupling block is

secured to gun or exit port is directed into flush pail.

F

IG

. 4 Manual Valves

To prevent release of pressurized chemical, close

both manual valves before removing coupling block.

Manual Valves