OM−05229

JSV3H

PAGE B − 2

INSTALLATION

PUMP INSTALLATION

Lifting

Use lifting equipment with a capacity of at least

990

lbs. (450 kg.)

. This pump weighs approximately

198 lbs. (90 kg.)

, including the weight of standard

cable, but

not

including the weight of customer-

installed accessories such as piping. Discharge

hose or piping must be removed before attempting

to lift the pump.

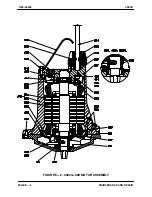

Positioning the Pump

NOTE

Before installing and operating the pump, check

the direction of impeller rotation to ensure that the

pump is properly wired at the control box. See

IM-

PELLER ROTATION

,

SECTION C.

This pump is designed with an automatic sub-

mersible connection which allows the pump to be

removed and/or installed without personnel enter-

ing the wet well.

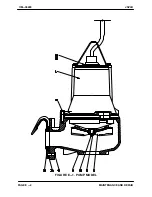

The pump is equipped with a rail guide shoe which

connects to the discharge optional elbow/

baseplate. When lowered into place, the pump is

automatically and securely connected to the el-

bow/baseplate and the piping system. See Figure

B−1 for a typical elbow/baseplate installation. For

information on installing the guide rails, see the lit-

erature accompanying them.

NOTE

When engaging the guide shoe and elbow/base-

plate, make sure that the connection is not impeded

by mounting hardware, and that the guide shoe is

fully seated in the baseplate.

Engage the guide shoe at the top of the guide rails,

and lower the pump into the sump. When the

pump and guide shoe engages the discharge el-

bow/baseplate, it will form an automatic seal.

Reel in any slack control cable so that it is not

dragged into the pump suction.

Piping

NOTE

Refer to

PERFORMANCE CURVES

in

OPERA-

TION − SECTION C

when determining the most ef-

ficient piping installation.

No suction piping is required in a standard sub-

merged operation.

The optional elbow/baseplate is drilled for a

3−inch discharge flange connection. Either hose

or rigid pipe may be used to make discharge con-

nections. The discharge line must be independ-

ently supported to avoid vibration and strain on the

pump. For maximum pumping capacity, keep the

line as short and straight as possible. Elbows and

fittings used in a discharge line increase friction

losses; minimize their use.

It is recommended that a check valve or throttling

valve be installed in the discharge line to control si-

phoning or back flow when the pump is shut off.

ELECTRICAL CONNECTIONS

Install and operate this pump in accor-

dance with the National Electrical Code

and all local codes. Have a qualified

electrician perform all checks and con-

nections in this section.

Never attempt to alter the length of the

pump motor cable or to repair it with a

splice. The power cable and pump mo-

tor must be kept completely waterproof.

Serious damage to the pump and injury

or death to personnel can result from

any alteration to the cable.