OM−05229

JSV3H

PAGE E − 8

MAINTENANCE AND REPAIR

as a unit, remove the allen screws (237), and

pull the assembly out of the motor cover (230).

7.

If desired to separate the parts removed in

Step 6, lubricate the motor cable (234) to ease

removal.

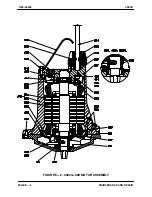

Removing Rotor and Shaft Assembly

1.

See

LUBRICATION

at the end of SECTION E,

and drain the oil from the motor housing (257).

2.

With the pump end components and motor

cover removed, tap the motor cover end of the

rotor and shaft assembly (201) with a soft-

faced mallet until the bearing housing (213)

comes free of the stator housing (302). Care-

fully slide the bearing housing and rotor and

shaft assembly out of the motor housing as a

unit.

3.

Remove the O-ring (252) from the groove in the

bearing housing.

NOTE

The stator (301) is a hot shrink fit in the motor hous-

ing (302). No instructions are given in this manual

for separating the stator, motor housing, or thermal

protectors (307). It is strongly recommended that

the stator/motor housing be returned to the factory

or an authorized Gorman-Rupp repair facility if any

of the components require service.

Removing Bearings

1.

Remove the retaining ring (206), and slide the

shaft and rotor and assembled bearings out of

the lower bearing housing.

2.

Remove the retaining ring (209), and support

ring (208) from the shaft.

NOTE

Because bearings can be damaged while being re-

moved, it is recommended that they be inspected in

place. The bearings are secured by a press fit onto

the shaft.

If the bearings will not be replaced, it is also recom-

mended that they be cleaned in place (see

IN-

SPECTION AND CLEANING

).

3.

If the bearings require replacement, use a

bearing puller to remove them from the shaft.

INSPECTION AND CLEANING

Carefully inspect all O-ring seating areas to deter-

mine if they formed a proper seal. If sealing was

faulty, determine the cause before reassembling

the pump. After inspection, remove and discard all

O-rings.

Most cleaning solvents are toxic and

flammable. Use them only in a well-ven-

tilated area free from flame, sparks, and

excessive heat. Read and follow all pre-

cautions printed on solvent containers.

Bearings

1.

It is recommended that bearings be cleaned in

place.

2.

Clean bearings thoroughly in

fresh

cleaning

solvent; dry with filtered compressed air. Ro-

tate the bearings by hand to check for rough-

ness or binding; replace as necessary.

3.

Coat external surfaces with light oil to ease

reassembly; these bearings are permanently

sealed and require no additional lubrication.

4.

Cover the bearings with clean cloth to keep ex-

ternal surfaces free of all dirt and foreign mate-

rial;

failure to do so could damage the bear-

ings or their mating surfaces

.

Other Reusable Parts (Except Seal Assembly)

1.

Thoroughly clean all reusable parts.