OM−05229

JSV3H

PAGE C − 2

OPERATION

Review all SAFETY information in Section A.

Follow the instructions on all tags, labels and

decals attached to the pump.

CONTROLS

The pump warranty is void if the motor is

not operated through a control box ap-

proved by Gorman-Rupp.

See the operating instructions furnished with the

control box, and with other optional accessories

and controls, before attempting to start the pump.

PUMP OPERATION

Liquid Temperature and Overheating.

Standard versions of this pump will handle

liquids with temperatures up to 104

_

F

(40

_

C) maximum. Do not install in service

with higher liquid temperatures; otherwise,

pump components and operation may be

affected.

Overheated pumps can cause severe

burns and injury. If the pump becomes

overheated:

1. Stop the pump immediately.

2. Allow the pump to completely cool.

3. Refer to instructions in this manual

before restarting the pump.

Overheating can occur if the control box fails to

provide overload or thermal protection, or if the

pump is operated against a closed discharge valve

for an extended period of time.

The submersible motor is cooled by the liquid be-

ing pumped. To minimize the chance of over-heat-

ing when installed in a

simplex

application, it is

recommended that at least one-third of the motor

remain immersed in the liquid.

Do not start the pump more than 10 times

per hour. If the motor does not cool be-

tween starts it will overheat, resulting in

damage to the motor windings or control

box components.

When installed in a standard alternating

duplex

application, where one pump runs while the other

is shut down, the pump may be operated continu-

ously until fully exposed. The shut down cycle will

provide sufficient time for the motor to cool.

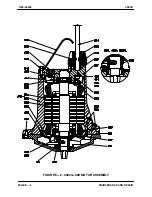

Impeller Rotation

Refer to Figure C−1, and check impeller rotation

as follows before installing the pump on rails or in a

wet well.

FIGURE C−1. PUMP ROTATION