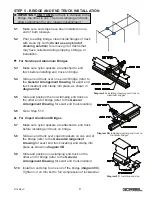

STEP 4 - RUNWAY OR MONORAIL INSTALLATION

Runway or Monorail to Header Weldment Connections

4.1

Suspend runway section under installed support

structure (refer to enclosed

General Arrangement

Drawing

for recommended dimensions and runway

or monorail location).

4.2

Using spine clamp angles, clamp plates, and

hardware provided, attach runway or monorail

section to header weldment, as shown in

diagram

4A

or

4B

.

4.3

Check to make sure that runway is level (/-

1/8”) and parallel to opposite runway (/- 1/4”)

over a 20’-0” distance.

4.4

Tighten hanger hardware to full compression of

lockwasher, do not exceed 50 ft.-lbs.

4.5

If you

DO NOT

have additional runways or monorails

to install, proceed to Step 4.13 on page 8 otherwise proceed to Step 4.6 on page 8.

Splice Joint Instructions

IMPORTANT:

To install additional runway sections, runways must be spliced together.

4.6

Attach hardware to splice joint. Slide splice joint over track portion of installed runway.

4.7

Lift next runway section into position for splicing to previously installed runway, bringing runway

ends together. Maximum gap between ends of load carrying flanges shall be less than or equal to

1/16” (1.5mm). Center lower splice joint over the two track ends (

diagram 4C

or

4D

, page 8).

WARNING

Do not deviate from the bridge “span” dimension

shown on the General Arrangement Drawing.

Bridge “span” is the distance between runways

(centerline to centerline).

IMPORTANT:

Keep in mind that splice joints must be

within 48” of hanger center.

IMPORTANT:

The closer the runways are to parallel

the easier the bridge is to move.

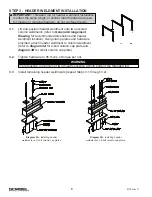

Diagram 4A.

Attaching runway to header

weldment (standard hangers).

7

9/18 Rev C

Diagram 4B.

Attaching runway to header

weldment (3-hole hangers).

WARNING

There must be a minimum of two threads showing

at both ends of the threaded rod.

WARNING

If 3-hole hangers are being used, one threaded

rod must be secured through the runway top tube.

Failure to do so may result in the runway falling to

the floor.

WARNING

Do not deviate from the dimensions specified in the General Arrangement Drawing for maximum

space from header center to splice joint. Typically 48” maximum.