2

9/18 Rev C

WARNINGS

1. Do not throw away these instructions.

2. A minimum of a 6”-think reinforced concrete floor is required. Gorbel, Inc. assumes no

responsibility for adequacy or integrity of the mounting surface.

3. Only competent erection personnel familiar with standard fabrication practices should be

employed to assemble these anchor systems. Gorbel is not responsible for the quality of

workmanship employed in the installation of an anchor system according to these

instructions. Contact Gorbel Inc. at 600 Fishers Run, P.O. Box 593, Fishers, New York

14453-0593, 800-821-0086, for additional information if necessary.

4. Read and understand this manual before using equipment.

5. This manual should be read and understood in its entirety, and used as part of a training

program as required by OSHA or any state and local regulatory agency.

6. This and any other included instructions must be provided to the users of this equipment. The

user must understand the proper equipment use and limitations.

7. The Tether Track® Anchor System is only to be used as part of a complete fall protection

system. The buyer or user is responsible for the safety and compatibility of the complete

system.

8. Any component replacement, addition or change to the anchor system or the complete

system requires evaluation by a qualified person.

9. Any fall event can result in injuries. The proper use of this equipment can substantially reduce

an injury. For maximum safety, the worker must be trained in the proper use of this

equipment and all of the components of the fall arrest system.

10. Before each use, the equipment shall be inspected as outlined in the inspection section of

this manual.

11. The rated capacity, the rated maximum arresting force and the rated number of workers of the

Tether Track® Anchor System must not be exceeded.

12. The maximum arresting force rating of the lanyard or SRL connected to the Tether Track® Anchor

System shall not exceed the rating of the Tether Track® Anchor System.

13. A managed fall protection program which includes a rescue plan is required for the safe use

of this equipment. A worker suspended from this system can lose vital blood flow to the brain

as blood pools in the legs. This is referred to as suspension trauma.

14. Reference the American Institute of Steel Construction (AISC) Manual of Steel Construction,

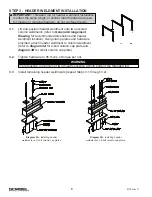

Specification for Structural Joints using ASTM A325 or A490 Bolts (section 8.d.2) for the

proper procedures to follow when using any torque tightening method.

15. Do not field modify the Tether Track® Free Standing Rigid Rail Anchor System in any way.

Any modifications without the written consent of Gorbel Inc. will void warranty.

16. Gorbel has ensured the compatibility of Tether Track®

ONLY

with a Gorbel® approved

connector (fall arrest trolley). It is the responsibility of the dealer or end user to ensure proper

design, function and compatibility of any trolley used with Tether Track® that has not been

validated by Gorbel for a fall arrest application.

17. Failure to follow these instructions can result in serious injury or death.

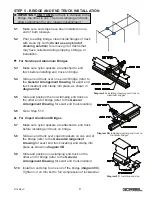

18. Support assemblies are designed to AISC (American Institute of Steel Construction)

specifications. If no movement of the support assembly is required, additional bracing (not

included) to the building steel structure is recommended.