STEP 5 - BRIDGE AND END TRUCK INSTALLATION (CONTINUED)

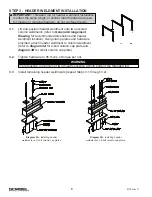

5.11

At both ends of bridge, install a shear lug bolt in hole at top of bridge (or in the coped

brackets) to prevent bridge from sliding out of end trucks. Install bolts with head of bolt on

underside of top flange with threads pointing up (

diagram 5A

or

5B

, page 9).

5.12

Lift bridge up to runway ends and simultaneously insert end trucks into open ends of

runways.

5.13

Immediately

install end stops in open ends of runways to prevent bridge from exiting

runways (refer to

diagram 4F

, on page 8).

5.14

Roll bridge down length of runways to check for smooth travel. If travel is not smooth,

check track for level and parallel (Step 4.3, page 7) and check to make sure that only one

end truck on bridge is clamped.

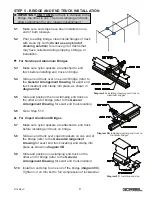

STEP 6 - TROLLEY INSTALLATION

6.1

Clean inside flanges of track with a clean, dry cloth

(

do not use any kind of cleaning solution

) to

remove grit or debris that may have collected during

shipping, storage, or installation.

6.2

Be sure end stop is installed in one end of bridge/

monorail.

6.3

Verify that the eyenut is securely fastened to the

trolley with the spring pin installed (refer to

diagram

6A

).

6.4

If using a self-retracting lifeline, attach

self-retracting lifeline to trolley eye nut

using ANSI approved hardware supplied

with lifeline. Refer to the self-retracting

lifeline manual.

6.5

Roll trolley into open end of track on

bridge/monorail.

6.6

Install end stop on the open end of bridge/monorail (

diagram 4F

, on page 8, or

5C

, on

page 9). Tighten nut on thru bolt to full compression of lockwasher.

10

9/18 Rev C

Diagram 6B.

F500 and Bridge Trolleys.

WARNING

Failure to install shear lug bolt assemblies may result in the bridge and worker falling to

the floor.

SPRING PIN

CLAMP PLATE

EYENUT

BLACK

SPRING

WASHER

GUIDE

BUSHINGS

Diagram 6A.

Tether Track® trolley installation.