11

221129A

4 H e a t i n g S y s t e m

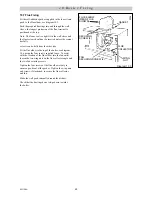

Diagram 4.3

METHOD 1

METHOD 2

METHOD 3

SUPPLY STOP

VALVE

SUPPLY

PIPE

HOSE

UNIONS

SERVICING

VALVE

TEMPORARY

HOSE

HEATING

SYSTEM

HEATING

SYSTEM

TEMPORARY

HOSE

HOSE

UNIONS

SERVICING

VALVE

SUPPLY

PIPE

SUPPLY STOP

VALVE

DOUBLE CHECK

VALVE ASSEMBLY

HEATING

SYSTEM

SERVICING

VALVE

SUPPLY

STOP VALVE

SUPPLY

PIPE

HOSE

UNIONS

DOUBLE CHECK

VALVE ASSEMBLY

OVERFLOW

CISTERN

COMBINED

CHECK VALVE

AND VACUUM

BREAKER

PRESSURE

REDUCING

VALVE

3132

5 D o m e s t i c H o t W a t e r S y s t e m

4.9 Filling Sealed Systems

Provision for filling the system at a low level must be

made. Three methods of filling are shown in

diagram 4.3.

There must be no permanent connection to the mains

water supply, even through a non-return valve.

4.10 Corrosion Inhibitor

If an inhibitor is to be used in the system, contact the

inhibitor manufacturer so that they can recommend their

most suitable product.

When fitting the boiler into an existing system, special

care should be taken to drain the entire system, including

radiators, then thoroughly cleaning out before fitting the

boiler whether or not adding an inhibitor.

4.11 Draining

A draining tap must be provided at the lowest points of

the system, which will allow the entire system to be

drained. An additional draining tap MUST be fitted

close to the boiler.

The flow and return isolation valves are provided with

drain points for boiler heat exchanger drainage.

5.1 General

The domestic hot water service must be in accordance

with the rules in force in the countries of destination.

5.2 Water Pressure

For the minimum and maximum working pressures of

the domestic hot water circuit of the boiler refer to

Section 1.6 Data.

If the cold water supply pressure exceeds the maximum,

a governor must be fitted in the supply to the boiler to

reduce the pressure to within the limits given.

5.3 “Hard” Water Areas

In areas where the water is “hard”, more than

200mg/litre, it is recommended that a proprietary scale

reducer is fitted in the cold water supply to the boiler.

Check the total water “hardness”, using the kit supplied,

in the door, following the instructions given. Consult the

local water company for additional advice.

A double check valve assembly must be fitted upstream

of the scale reducer. For the relative position of the scale

reducer and pressure reducing valve, if required, refer to

the manufacturer’s instructions.