24

221129A

1 1 C o m m i s s i o n i n g

11.5 Burner Pressure - Hot Water -

Honeywell

The burner pressure is factory preset and no adjustment

should be required.

Connect the electrical supply; the pump and fan will

operate for about 30 seconds, then the fan will reduce

speed and the pump stop.

Relight the pilot burner.

Fully open the largest hot water draw off tap whereby

the main burner will light, the flames gradually

increasing to the maximum.

Check the soundness of the boiler gas joints, with the

main burner on, using a leak detection fluid. Take care

not to splash any of the electrical components.

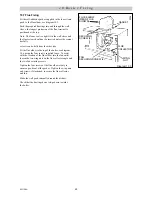

Fully open the hot water throttle, (clockwise), see

diagram 11.5. Check that the water flow rate is not less

than 9Litre/min. (2.0gall/min) to prevent any modulation

of the gas pressure. This is equivalent to 6.7 seconds to

fill a 1Litre container (3.8 seconds for 1pint).

To achieve this flow rate a water pressure of at least

0.8bar is required during commissioning, although

subsequently the appliance will work at a minimum

pressure of 0.5bar.

This flow rate should prevent any modulation of the

gas pressure.

Check the burner pressure is /-0.35mbar

(+/-0.14in wg). of 15.7mbar (6.3in wg), the hot water

burner pressure. If this is incorrect, the burner pressure

may be adjusted to the correct setting by turning the hot

water gas pressure adjuster (potentiometer), using an

insulated screwdriver, see diagram 11.6. Gain access to

the adjusters on the control board by removing the

control housing cover, see diagram 10.1. Turn the

adjuster slowly, always making adjustment by reducing

below the required pressure then increasing up to the

required setting, (turn clockwise to increase).

Close the hot water draw off.

If the maximum pressure cannot be obtained, check that

the gas supply of adequate size, refer to Section 1.8.

11.5 Burner Pressure - Hot Water - SIT

The burner pressure is factory preset and no adjustment

should be required.

Connect the electrical supply.

Relight the pilot.

Turn gas control knob “D” to “

“, main burner

position.

Fully open the largest hot water draw off tap whereby

the main burner will light, the flames gradually

increasing to the maximum.

Check the soundness of the boiler gas joints, with the

burner lit, using a suitable leak detection fluid. Take

care not to splash any of the electrical components.

Fully open the hot water throttle, (clockwise), see

diagram 11.5. Check that the water flow rate is not less

than 9Litre/min (2.0gall/min) to prevent any modulation

of the gas pressure. This is equivalent to 6.7 seconds to

fill a 1Litre container (3.8 seconds for 1pint).

To achieve this flow rate a water pressure of at least

0.8bar is required during commissioning, although

subsequently the appliance will work at a minimum

pressure of 0.5bar.

This flow rate should prevent any modulation of the gas

pressure.

Check that the burner pressure is 16.1mbar +/- 0.35mbar

(6.5in wg +/- 0.14wg) If this is incorrect, the burner

pressure may be adjusted by turning the larger brass

adjusting nut of the modulator, anti-clockwise to

decrease, after removing the cap, see diagram 11.2.

Fine adjustment may be achieved by turning the hot

water gas pressure adjuster (potentiometer), using an

insulated screwdriver, see diagram 11.6. Gain access to

the adjusters on the control board by removing the

control housing, see diagram 10.1.

Turn the adjuster slowly, always making adjustments by

reducing below the required pressure then increasing up

to the required setting, turn clockwise to increase.

Close the hot water draw off.

If the maximum pressure cannot be obtained, check that

the gas supply is of adequate size, refer to Section 1.7.