Instruction Manual ZS100T, ZS150T & ZS200T Series II (MAM-870) Senator Industrial Air Compressors

23

4.8

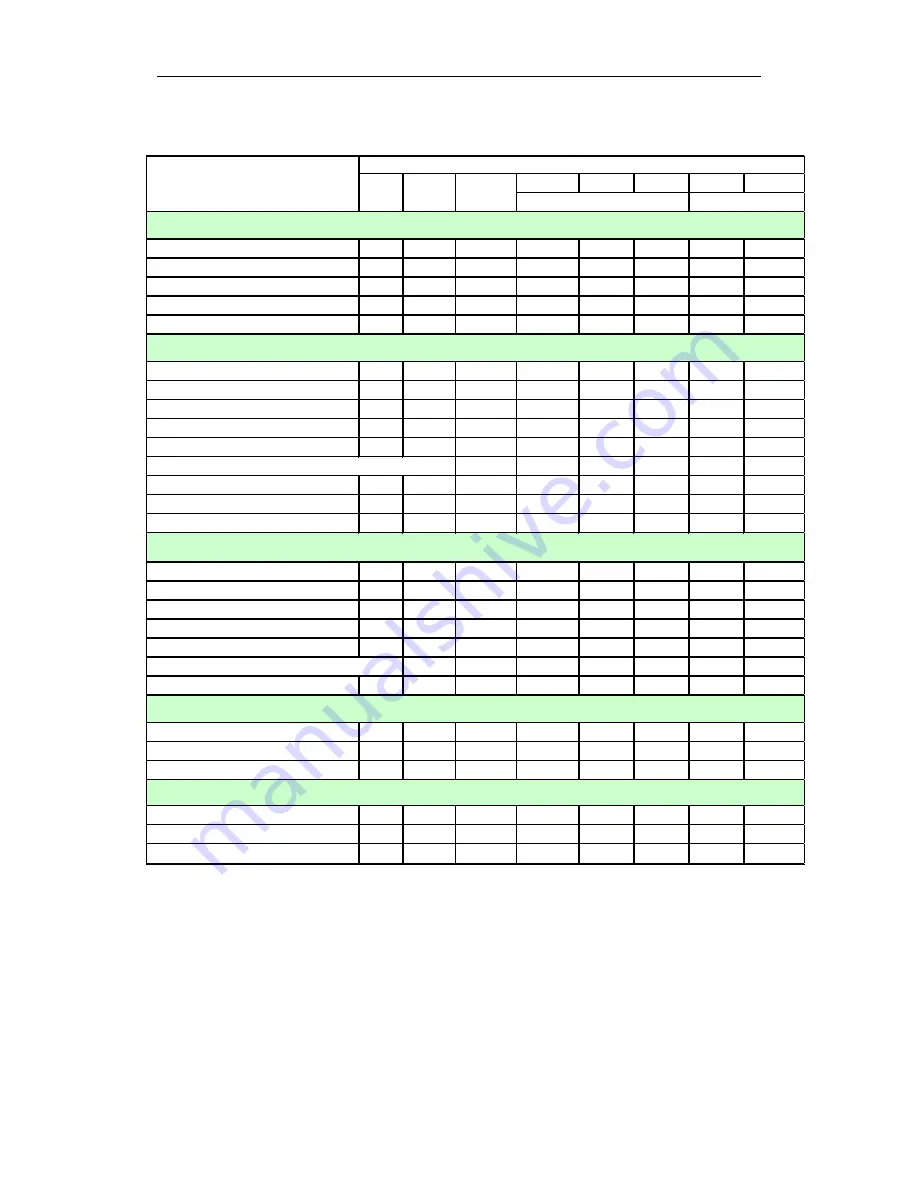

Preventative Maintenance Program

¹ Using mineral based compressor lubricating oil; 2,000 hours maximum or 1 year.

² Using synthetic based compressor lubricating oil; 8,000 hours maximum or 1 year.

*

Applicable to the model equipped with air filter condition indicator.

**

In adverse working conditions such as dusty environment and high temperature,

the maintenance or replacement interval should be reduced.

1,000

2,000

4,000

6,000

8,000

Check oil level

√

Check tightness of components

√

Check correct indication of meters

√

Check maintenance indicator of air filter

√*

Drain out condensate after shutdown

√

Clean or replace air inlet screen, if fitted

√

Clean air filter element

√

Replace air filter element

√

Clean fittings of inlet valve

√

Replace maintenance kit of inlet valve

√

Replace maintenance kit of minimum pressure valve

√

Clean oil cooler

√

Check pressure transducer

√

√

Check safety valves

√

Replace oil for new machine

√

Initial

Add lubricating oil (if necessary)

√

Check cleanliness in oil return pipe

√

Replace oil filter

√

Initial

√

Replace oil-air separator element

√

Replace maintenance kit of thermostatic valve

√

Replace oil

√

①

√

②

Check or adjust V-belt tension

√

Initial

√

Check or replace V-belts

√

Add lubricating grease for motor bearings

√

Check emergency stop button

√

Check reliability of electrical connection

√

Check controller for its normal functions

√

Electrical system

Drive system

Oil circuit system

Air system

Daily maintenance works

Maintenance items

Maintenance interval (based on operating hours)**

Daily

Quarterly

Weekly

1 Year

2 Years

Содержание MAM-870

Страница 2: ......

Страница 8: ...Instruction Manual ZS100T ZS150T ZS200T Series II MAM 870 Senator Industrial Air Compressors 4...

Страница 39: ......

Страница 40: ......

Страница 41: ...INSTRUCTION MANUAL MAM 870 COMPRESSOR CONTROLLER...

Страница 42: ......

Страница 58: ...NOTES...

Страница 59: ......

Страница 60: ......