8

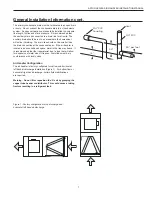

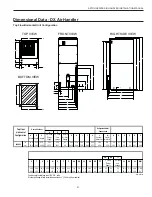

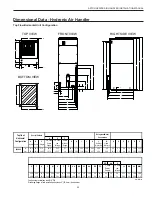

Bottomflow Application

To convert the air handler for bottomflow applications follow the

steps shown below:

1. Remove all access panels. Disconnect the blower

harnesses from the motor and loosen ground wire from

blower. Remove the blower by removing 2 screws from

the blower mounting bracket, and slide the blower

assembly out the front. Remove the stiffener bracket in

front of coil, 'A' coil/pan assembly and the horizontal

drain pan. This will lighten the cabinet and make it easier

to

maneuver.

2. Rotate the cabinet 180° from the upright position so that

the discharge air opening is located at the bottom and

the return air opening is at the top.

3. Install the blower assembly into the blower discharge

opening at the bottom of the cabinet by sliding the

blower mounting bracket under the discharge support

bracket and secure in place with 2 screws. The blower

harness and motor ground wire should be reattached

before sliding the blower into place.

4. On the 042-060 install the NAHBC bottomflow

conversion kit per instructions in the kit. Failure to install

this kit will result in condensate blow-off from the 'A'

coil into the cabinet and ductwork.

5. Install the 'A' coil into the upper section of the cabinet

as pictured in Figure 2. Attach the stiffener bracket into

the two holes provided in the cabinet so that the bracket

is in front of the coil. The horizontal drain pan is not

needed and must be discarded. Plug the 2 drain hole

openings in the access panel with the plugs provided.

6. Replace the access panels.

7. Bottom air discharge units require the supply air opening

to be cut at least a 1/2” larger than the unit’s air outlet.

8. When installed on combustible flooring, protect the

edges of the floor opening with sheet metal over wrap or

other non-combustible material.

9. Bottom air discharge units should be sealed well to the

floor to prevent air leakage.

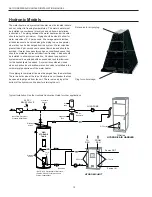

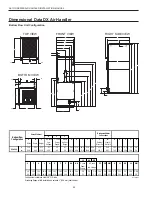

Horizontal Right Air Discharge Application

To convert air handler for horizontal right air discharge applications

follow the steps shown below

1. Remove all access panels. Remove the stiffener bracket

in front of the coil, ‘A’ coil assembly and the horizontal

drain

pan.

2. From the vertical upflow position, rotate the top of the

cabinet 90° to the right and set in place.

3. Remove the support bracket mounted to the top plate of

the ‘A’ coil. Rotate the ‘A’ coil support bracket 180° from

its original position and re-attach into existing holes in

the top plate of the coil. This must be done to prevent

the ‘A’ coil from falling into the drain pan (Figure 3).

4. Move the horizontal drain pan from the left side of the ‘A’

coil to the right hand side of the ‘A’ coil. Place the ‘A’ coil

and horizontal drain pan assembly into the cabinet

so that the support bracket is resting in the horizontal

drain pan as shown in Figure 3. Attach the stiffener

bracket into the two holes provided in the cabinet so that

the bracket is in front of the coil.

5. Remove the 2 drain plugs from the upper right of the

access panel and install them on the lower left of the

access panel. Replace the access panels.

6. If the unit is suspended, the entire length of the cabinet

should be supported.

Important: When removing the coil, there is possible danger

of equipment damage and personal injury. Be careful when

removing the coil assembly from the unit.

Figure 2 - Bottomflow Air Handler

Figure 3 - Horizontal Right Hand Air Discharge

Rotate the coil support bracket to this position

General Installation Information cont.

ASTON SERIES AIR HANDLER INSTALLATION MANUAL