19

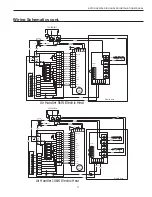

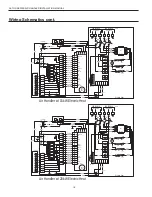

ECM Blower Control

The ECM blower motor is controlled by an interface board installed

in the air handler and allows field selectable CFM settings. The

interface board receives inputs from the thermostat and converts

them to signals used by the ECM motor. There are four different

airflow settings that are field selectable via DIP switches (see

Blower Performance table).

Cooling/Heating settings

The cooling/heating CFM settings determine the normal cooling/

heating CFM when the unit is not in dehumidification mode or

auxiliary heat mode. DIP switches 1 and 2 ‘off’ is the lowest CFM

setting while with DIP switches 1 and 2 ‘on’ is the highest CFM

setting. To prevent air coil freeze up, the lowest CFM setting can

not be used when dehumidification mode is selected. DIP 9 must

be ‘on’ to enable normal airflow settings.

Dehumidification Mode settings

This setting provides for field selection of humidity control (via

setting DIP 9 ‘off’). The cooling airflow settings are determined by

the Cooling/Heating DIP switch settings above. Dehumidification

mode reduces the selected normal cooling CFM by 15%-20%

which increases the moisture removing capability of the heat pump.

To prevent air coil freeze up, the lowest CFM setting can not be

used when dehumidification mode is selected.

Dehumidification Mode (Continuous) – This mode is selected via

setting DIP 9 ‘off’ on the ECM interface board and will be engaged

whenever an ‘O’ input is present. In this mode any time the unit is

operating in cooling mode, it will run at a CFM level 15%-20% lower

than the selected normal cooling CFM.

NOTE:

Do not select dehumidification mode if the lowest Cooling/

Heating airflow level is selected (DIPS 1 & 2 off).

Auxiliary Heat settings - DIP 5 & 6 on the ECM interface board are

used to select the desired CFM in auxiliary/emergency heat mode.

Whenever auxiliary or emergency electric heat is energized this air

flow setting will be used.

ASTON SERIES AIR HANDLER INSTALLATION MANUAL