6

General Installation Information cont.

Moving and Storage

If the equipment is not needed for immediate installation it should

be left in its shipping carton and stored in a clean, dry area. Units

must only be stored or moved in the normal “up” orientation.

Unit Location

Locate the unit in an indoor area that allows for easy removal of

the filter and access panels (the air handler units are not approved

for outdoor installation). Location should have enough space

for service personnel to perform maintenance or repair. Provide

sufficient room to make refrigerant, electrical and duct connections.

If the unit is located in a confined space, such as a closet,

provisions must be made for return air to freely enter the space

by means of a louvered door, etc. The air handler section may be

installed on any level surface strong enough to support its weight.

When installed in a closet or on a stand, it should be mounted

on vibration absorbing material slightly larger than the base to

minimize vibration transmission to the building structure.

When installed in an attic or above a drop ceiling, the installation

must conform to all local codes. If the unit is suspended and

installed in the horizontal position, the entire length of the unit

should be supported. If the application requires the air handler to

be installed on the attic floor then the unit should be set in a full

size secondary drain pan. In this case the secondary drain pan

should be set on top of a vibration absorbing mesh. The secondary

drain pan is usually placed on a plywood base. A secondary drain

pan should be used when equipment is installed over a finished

living area to provide protection from water damage in case of

plugging of the air handler primary drain line. The secondary drain

line should terminate somewhere that is easily visible by the

homeowner. Be certain to show the homeowner the termination

location of the secondary drain line and to explain its purpose.

Duct System

The duct system should be sized to handle the design airflow

quietly and efficiently. To maximize sound attenuation of the unit

blower, the supply and return plenums should include an internal

duct liner of fiberglass or constructed of ductboard for the first

few feet. On systems employing a metal duct system, canvas

connectors should be used between the unit and the ductwork. If

air noise or excessive airflow is a problem, the blower speed can

be changed. Application of the unit to un-insulated metal ductwork

in an unconditioned space will cause poor unit performance and

allow condensation to form on the duct and possibly cause damage

to the structure.

If the unit is connected to existing ductwork, check the duct

system to ensure that it has the capacity to accommodate the air

required for the unit application. If the duct is too small, as in the

replacement of heating only systems, larger ductwork should be

installed. All existing ductwork should be checked for leaks and

repaired as necessary.

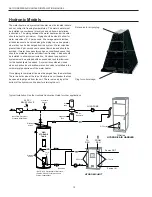

Condensate Drain

To facilitate condensate removal, the air handler should be pitched

1/4” towards the drain in both directions. The drain line contains

cold water and should be insulated in unconditioned spaces to

avoid drain line condensation from dripping on ceiling, etc. The

drain pan has a primary and auxiliary drain connection. The

21S521A03 condensate hose assembly kit is provided to connect

the drain pan's primary stainless steel tube to the PVC coupling

The air handler drain connections must be connected to a drain line

and pitched away from the unit a minimum of 1/8” per foot to allow

the condensate to flow away from the air handler.

A trap must be

installed in the drain line

below the bottom of the drain pan to

ensure free condensate flow (units are not internally trapped).

ASTON SERIES AIR HANDLER INSTALLATION MANUAL

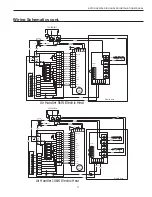

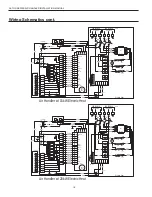

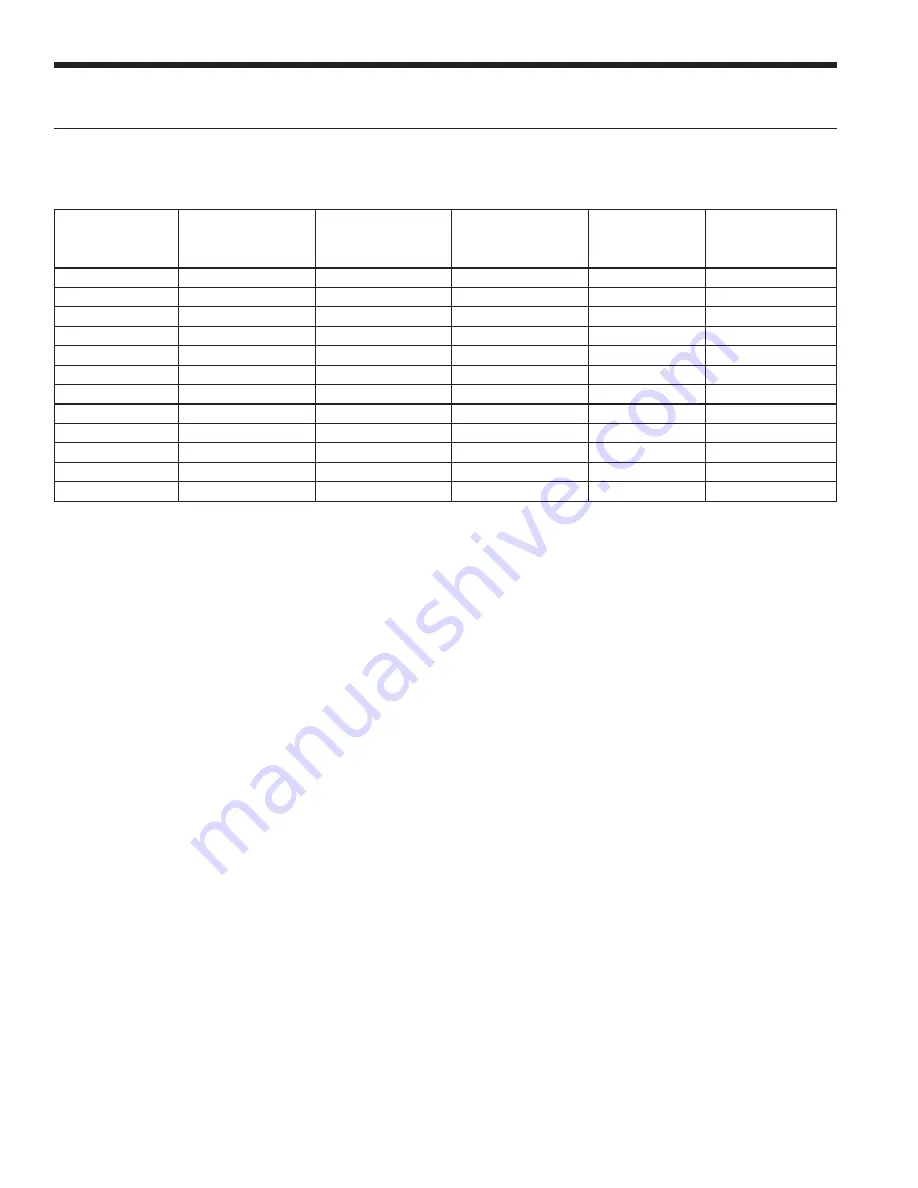

Air Handler Sizing Selection

The Aston Series Air Handlers are designed for R410a refrigerant and should be matched with Aston indoor and outdoor series

compressor section according to the table below.

Air Handler

Indoor Split Model

(Single)

Indoor Split Model

(Dual Capacity)

Outdoor Split Model

(Dual Capacity)

Airfl ow(CFM)

Electric Heat (kW)

GAH022B***1R

103*022

-

800

5

GAH026B***1R

-

103*026

104*026

925

5

GAH030B***1R

103*030

-

-

980

5, 10

GAH036B***1R

103*036

-

-

1225

5, 10

GAH036B***1R

-

103*038

104*038

1225

5, 10

GAH042B***1R

103*042

-

-

1425

10, 15

GAH048B***1R

103*048

-

-

1625

10, 15

GAH048B***1R

-

103*049

104*049

1625

10, 15

GAH060B***1R

103*060

-

-

1760

10, 15, 20

GAH060B***1R

-

103*064

104*064

1760

10, 15, 20

GAH060B***1R

103*070

-

-

1760

10, 15, 20

GAH060B***1R

-

103*072

104*072

1760

10, 15, 20

6/9/08