The controller determines, on the basis of the dynamics of the

process, the control output for the valve corresponding to the

opening of the same in such a way so as to maintain the

desired value of the process variable.

With counter-reaction valves the position is normally provided

by a potentiometer assembled on the actuator.

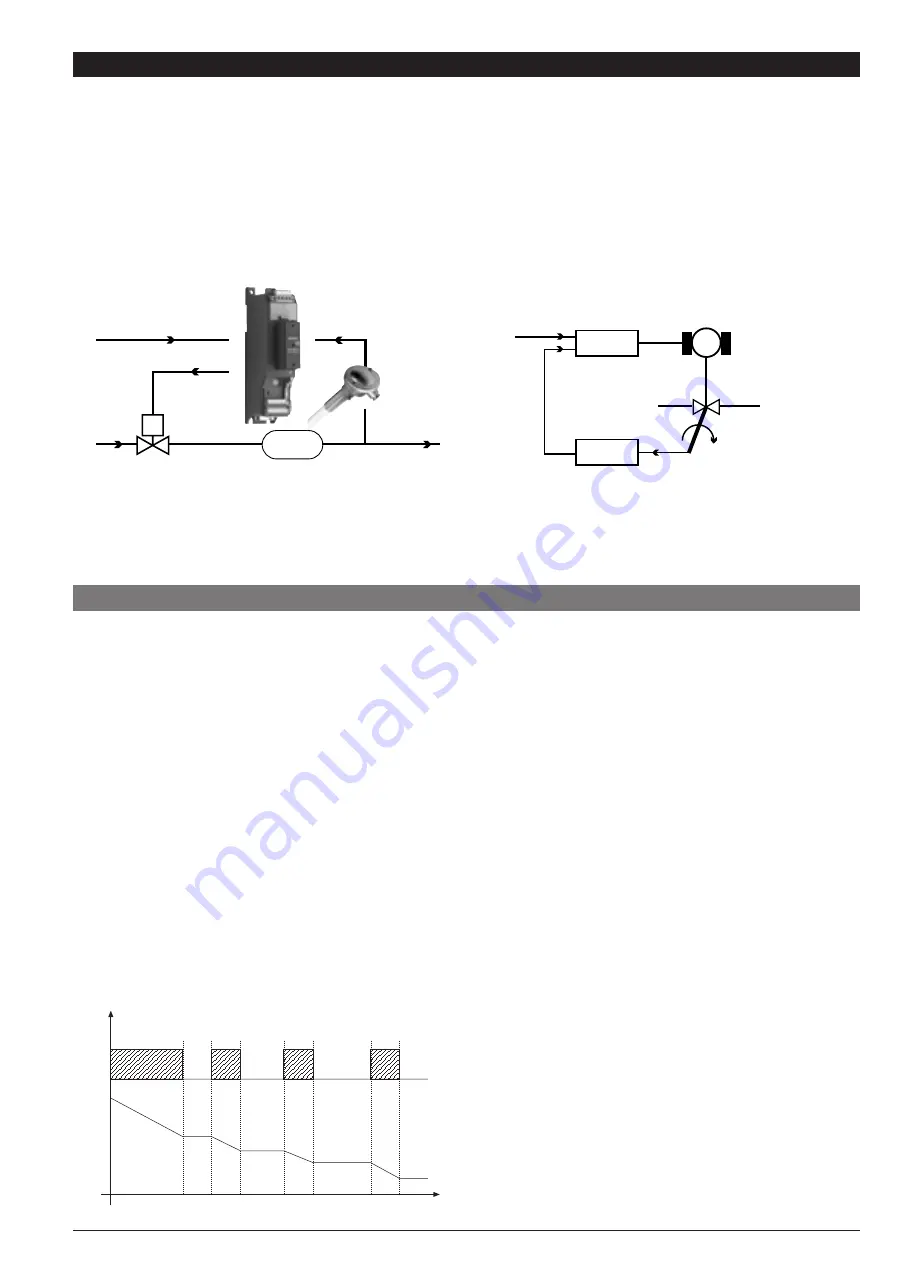

5 • ADJUSTMENT WITH MOTORIZED VALVE

Adjustment valve

Actuator

SetPoint

Process

M

CONTROL EXAMPLE FOR V0 VALVE

VALVE POSITION CONTROL

Control

Motor

Adjustment valve

Desired position

Process

variable

Valve position

feedback

potentiometer

In an adjustment process the adjustment valve has the

function of varying fuel delivery (frequently corresponding to

the thermal energy introduced into the process) in relation to

the signal coming from the controller.

For this purpose it is provided with an actuator able to modify

its opening value, overcoming the resistances produced by

the fluid passing inside it.

The adjustment valves vary the delivery in a modulated

manner, producing finite variations in the fluid passage inner

area corresponding to finite variations of the actuator input

signal, coming from the controller. The servomechanism, for

example, comprises an electric motor, a reducer and a

mechanical transmission system which actions the valve.

Various auxiliary components can be present such as the

mechanical and electrical safety end travels, manual actioning

systems, position location.

5.1 Characteristic parameters for valves control

- Actuator time (_At_) is the time employed by the valve to

pass from entirely open to entirely closed (or vice-versa), and

can be set with a resolution of one second.

It is a mechanical feature of the valve+actuator unit.

NOTE: if the actuator’s travel is mechanically limited it is

necessary to proportionally reduce the _At_ value.

- Minimum impulse (t_Lo) expressed as a % of the actuator

time (resolution 0.1%).

Represents the minimum change in position corresponding to

a minimum change in power supplied by the instrument below

which the actuator will not physically respond to the

command.

This represents the minimum variation in position due to

which the actuator does not physically respond to the

command.

The minimum duration of the movement can be set in t.on,

expressed as a % of actuator time.

- Impulsive intervention threshold (t_Hi) expressed as a % of

the actuator time (resolution 0.1%) represents the position

displacement (requested position – real position) due to which

the manoeuvre request becomes impulsive.

You can choose between 2 types of control:

1) ON time of movement = t.on and OFF time proportional to

shift and greater than or equal to t_Lo (we recommend setting

t.on = t.Lo) (set t.off = 0).

2) ON time of movement = t.on and OFF time = t.off. A value

set for t.off < t.on is forced to t.on. To activate this type, set

t.off < > 0.

The type of movement approach allows fine control of the

reverse drive valve (from potentiometer or not), especially

useful in cases of high mechanical inertia.

Set t_Hi = 0 to exclude modulation in positioning.

This type of modulated approach allows precise control of the

feedback actioned valve, by a potentiometer or not, and is

especially useful in cases of high mechanical inertia. Setting

t_Hi = 0 excludes modulation in positioning.

- Dead zone(_db_) is a displacement band between the

adjustment setpoint and the process variable within which the

controller does not supply any command to the valve (Open =

OFF; Close = OFF).

It is expressed as a percentage of the bottom scale and is

symmetrical with respect to the setpoint.

The dead zone is useful in an operative process to avoid

straining the actuator with repeated commands and an

insignificant effect on the adjustment. Setting _db_ = 0 the

dead zone is excluded.

t_Hi

t_Lo

t_Lo

t_Lo

t0

t1

t2

Graph of behavior inside the band with integral

time ¤ 0.

With integral time = 0, movement ON time is

always equal to OFF time.

t0 = t_Lo

13

80346B_MHW_GFX-VALVOLE_0709_ENG