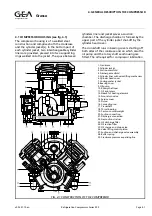

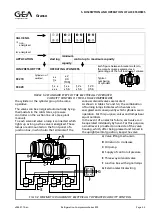

6.1 UNLOADED STARTING

When the compressor is at standstill, the suction

valve rings in all cylinders have been lifted

mechanically by the valve lifting mechanism.

As soon as the compressor is started, the oil pump

starts to build up pressure in the lubricating oil

system. However, the control oil pressure required

for controlling the valve lifting mechanisms,

remains locked for about one minute due to the

action of the time delay valve, incorporated in the

oil pump. During the period the compressor

attains its operating speed under no-load

conditions, whereby the gas drawn into the

cylinders is returned again to the suction

chambers and the suction manifold via the lifted

suction valves. The energy consumption is thus

limited to overcoming the starting torque which

consists of the pull-out torque, the frictional losses

and the flow losses in the suction valves. This

prevents a peak load of the electric power system

and overlading of motor, drive and equipment.

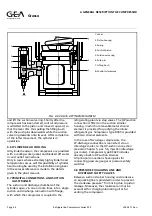

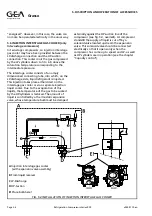

6.2 LOADED OPERATION OF COMPRESSOR

After the delay time has elapsed, the control oil

system is pressurized. for compressors without

capacity control this means that all cylinders are

operated simultaneously, as their valve lifting

mechanism becomes operative and the suction

valves come into action. For compressors provided

with capacity control, a limited, minimum

allowable number of cylinders is operated direct

by the control pressure; the other cylinders can, if

required, be cut in or out manually via the oil

distributor or electrically via the three-way

solenoid valves (refer also to Chapter 8,

Supervision during compressor operation).

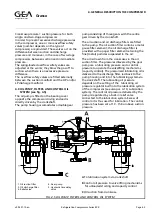

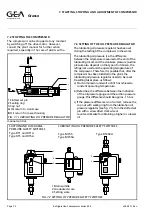

6.3 LIQUID HAMMER

Liquid hammer occurs when, together with the

refrigerant vapour, liquid is drawn in and forced

away. As liquid is not compressible, liquid hammer

may cause a sudden impact load on valves and

moving parts, which may result in more or less

serious damage to the compressor.

The relevant liquid may be either oil or liquid

refrigerant. Liquid hammer is reflected in a

distinctly audible, sometimes jerking stroke at

each revolution. When the phenomenon is

symptomatic, the installation engineer should be

consulted.

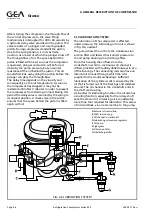

It is sometimes difficult to find out the sort of

liquid hammer. Frosting of the cylinder jacket as

well as an abnormally low discharge gas

temperature may point to the fact that liquid

refrigerant is being sucked. Even when no audible

liquid hammer occurs (the liquid then retains its

misty form), the valves may be damaged due to

excessive thermal load. Damage due to an

incidental, slight liquid hammer is prevented by

means of a buffer spring on the valve assembly

(see Chapter 4 fig 4.3).

Refrigeration Division

Grasso

6. OPERATION OF THE COMPRESSOR

v002.97.10.en

Refrigeration Compressors Series RC9

Page 6.1