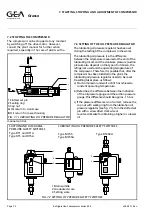

the cylinder or the cylinder group to become

operative.

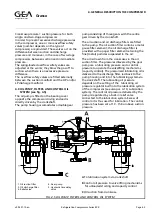

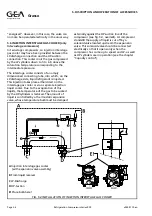

The valves can be energized automatically by e.g.

thermostats in the cold stores, a pressure

controller on the suction line, etc. (see plant

manual).

To each solenoid valve a lamp is connected which

lights up as long as the valve is energized. These

lamps are all mounted on the front panel of a

junction box, in which also the terminals of the

various solenoid valves are located.

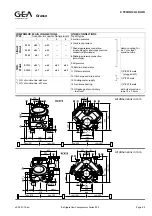

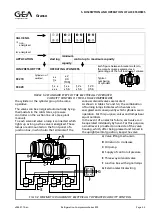

As shown in tables 5.2 and 5.3, the combination

of burning lamps indicates which valves are

energized and consequently which cylinders are in

operation. For this purpose, valves and lamps bear

equal numbers.

In the event of an electric failure, each valve can

be operated indvidually by hand. For this purpose,

a small lever is provided on one side of the valve

housing, which, after being pressed and turned in

the upright(vertical) position, keeps the valve

VALVE NO.

m

non-

energized

l

energized

APPLICATION

starting

minimum

capacity

control up to maximum capacity

COMPRESSOR TYPE

OPERATING CYLINDERS

Each figure between brackets refers to

the swept volume expressed as a

percentage of the full load swept volume

RC219

Cylinder no.1

omitted

•

•

3

•

•

2

3 4

(100)

Typical

numbering

of cylinders

RC429

1

•

•

•

•

•

1

•

•

•

5 6

1 2

•

•

5 6

1 2 3

4 5 6

TABLE 5.3 STANDARD STEPS OF THE ELECTRICALLY OPERATED

CAPACITY CONTROL OF TWO—STAGE COMPRESSORS

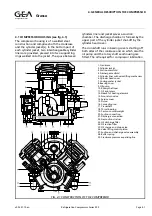

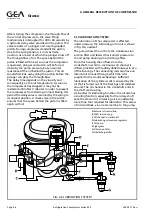

FIG. 5.3 SCHEMATIC DIAGRAM OF ELECTRICALLY OPERATED CAPACITY CONTROL

A

Valve lifting mechanism

B

Oil return to crankcase

C

Oil pump

D

Supply of control oil pressure

E

Three-way solenoid valve

F

Junction box with signal lamps

G

External electrical wiring

Refrigeration Division

Grasso

5. DISCRIPTION AND OPERATION OF ACCESSORIES

v002.97.10.en

Refrigeration Compressors Series RC9

Page 5.5