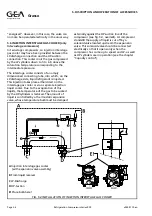

pressure respectively, until the required

pressure difference has been achieved. After

resetting,

replace the cap nut with sealing ring on the

pressure regulator.

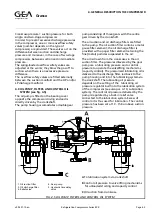

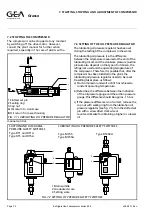

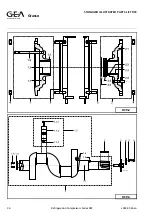

7.4 SETTING OF PRESSURE SAFETY SWITCHES

(see fig. 7.2)

The discharge pressure and suction pressure

safety switches

must be set at the values

indicated in the plant manual. The discharge

pressure safety switch must be set at a value

which is lower than the maximum discharge

pressure of the compressor (see chapter 3,

Technical data of compressor).

Setting is effected by turning the main spindle

with a spanner, after the cap on top of the

housing has been removed. The set value can be

read from a graduated scale in the front cover.

The lubricating oil pressure safety switch

must be

set at 1 bar, which is the minimum allowable

difference between oil pressure and crankcase

pressure (= sucton pressure). Setting takes place

by turning the setting disc with a screw driver; this

setting disc is accessible after the front cover has

been removed. The set value can be read from a

graduated scale.

Refrigeration Division

Grasso

7. STARTING, STOPPING AND ADJUSTMENT OF COMPRESSOR

v002.97.10.en

Refrigeration Compressors Series RC9

Page 7.3