30

D

GB

F

E

I

96403-08.2019-DGbFEIRu

5

|

Electrical connection

Pay attention to safety rules during service or repair work! Consider applicable laws, standards,

directives and possible new regulations before placing back into operation.

Use only new original parts when replacing old ones (e.g. cable screw connections).

Operate the electrical system only in an undamaged and clean condition; have it

checked and serviced at regular intervals by trained personnel.

Carefully make conductor connections so that individual wires are not damaged.

Properly prepare conductor ends of multiple-wire or fine-wire cables. Crimp wire end sockets only

with suitable compression tools to achieve uniform quality. Ensure a secure connection of all termi

-

nal locations!

Check installation before start-up.

The accompanying INT69 EX2 release unit must be installed corrosion-free in the external switch

cabinet outside the explosion-endangered area. Max. sensor cable length 30 m. Wire the release

unit as the first member in the control power circuit and protect it with a fuse that is rated no larger

than the smallest maximum permissible current of the installed component

.

When installing control and regulating parts, the respectively valid national regulations for Ex pro

-

tection must be observed!

When using the 24 V DC control voltage version of the Motor Protection Unit INT69 EX2, a protection

class 3 (SELV or PELV) safety transformer must be installed in series. The safety transformer must

conform to EN 60950-1.

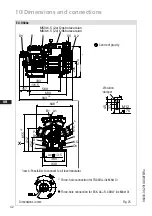

5.8 Electronic trigger unit INT69 EX2

ATTENTION Install INT69 EX2 outside the explosion-endangered area.

The INT69 EX2 trigger unit must be installed according to the wiring

diagram.

INFO

The relay switching output is executed as a floating changeover

contact. This electrical circuit operates according to the quiescent

current principle, i.e. the relay drops into a the idle position and

deactivates the motor contactor even in case of a sensor break or

open circuit.

The hot gas sensors of the cylinder cover and the temperature sensors of the motor are observed by

the electronic trigger unit INT69 EX2. In case of excess temperature in the motor winding and/or in

the hot gas, the INT69 EX2 deactivates the motor contactor. Once cooled, it can be restarted only if

the electronic lock of the output relay (terminals 1+2) is released by a mains reset > 5 sec

.

The INT69 EX2 fulfills the requirements of the IPL 1 (Ignition Prevention Level) as prescribed in the

EN 80079-37 and has an appropriate EX identification.

The unit trips when an overload or inadmissible operating conditions occur. Find and remedy

the cause.

WARNING

With the 24 V DC version of the INT69 EX2 triggering unit there is no

galvanic separation between small voltages and current supply. For

this reason, appropriate measures against electrical shock must be

provided, also for the current supply unit and further components

that are connected directly with the power supply if users can have

access to them.