MA-041

–

DGA 900 Plus - Installation & Commissioning Manual - Rev 1.1

4-Mar-22

Page 71 of 99

10

COMMISSIONING & SERVICE

This section details essential operational tasks and all first start-up procedures that

need only be performed once as part of the commissioning phase to prepare the product

for deployment in the field. Refer to the relevant sections below depending on the

installed options.

Note:

A familiarity with the interface is assumed. If not, refer to the

‘MA

-040

–

DGA

900

–

Plus Operator Guide

’

for login details and general HMI functionality.

Installation and commissioning must be performed by trained field service

engineers only. Resetting certain attributes may lead to data loss if the

product is already operational.

Check that all the installed inputs connected to a signal for the thermal,

cooling and OLTC cards are reading values within expectations.

After installation, check that the pulled current by every cooling bank unit is

within 5% of the value entered in the cooling configuration page. If not,

update the values in the Cooling Configuration page to the measured

values and let the asset operator know that those values have changed.

At the time of commissioning, reset all models as outlined in this section

including parameters, counters and all related model data.

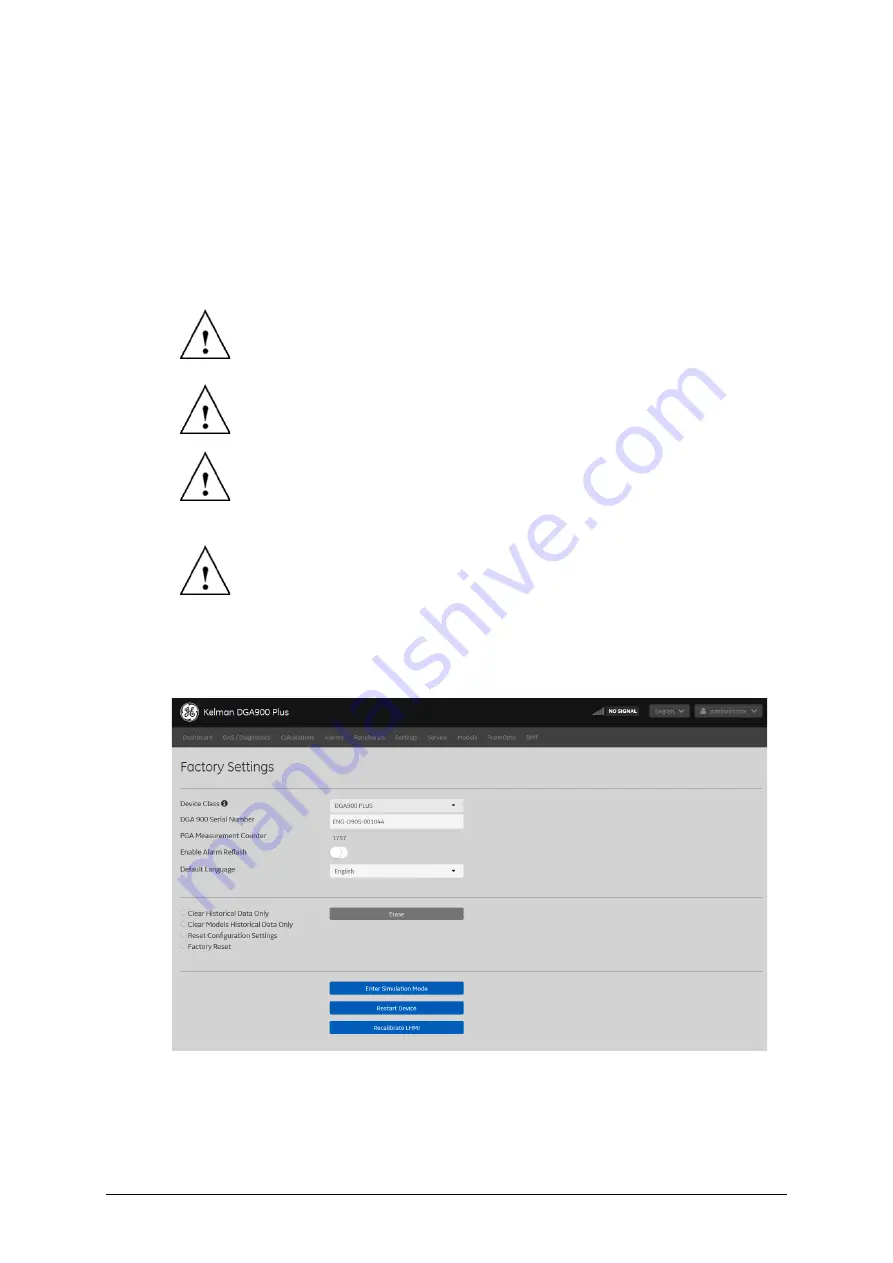

10.1

Factory Settings

Select

Service > Factory

to view the Factory Settings page as shown in Figure 10-1.

Figure 10-1: Service > Factory Settings

Select

Clear Historical Data Only

to erase all historical data including that associated

with models.