www.fiberoptions.com

free phone: 800.342.3748

free fax: 877.342.3732

10

If test patterns are enabled a grey screen with two white verti-

cal bars will be output. If test patterns are disabled the screen

will be black.

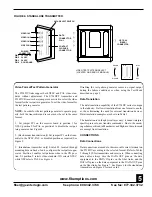

VIDEO IN (or OUT) Indicator

This LED indicates the presence of a video signal. VIDEO IN

on the transmitter remains green as long as an adequate video

signal is being input to the transmitter.

The LED will be red when no video signal is present. The

VIDEO OUT LED on the receiver performs a similar function,

except that it refers to the video that is output from the receiv-

er. If test patterns are enabled a grey screen with a single white

vertical bar pattern will be output when no video is present. If

disabled, the screen will be black.

NOTE:

The S734DV monitors the video sync signals to deter-

mine the presence of the signal. It does not monitor the picture

brightness signal. Thus, if the scene in front of a camera is

totally dark, producing a blank monitor screen, the VIDEO

LEDs will still be green.

DATA IN Indicator

The DATA IN LED indicates the state of the data being input

to the S734DV over copper. A green DATA IN LED indicates

a logic HIGH is present on the copper inputs. A yellow DATA

IN LED indicates a logic LOW is present on the copper. No

color (OFF) indicates a tri-state or high impedance input.

Therefore, this can be used to determine the resting state of

your equipment. Unique to the industry, the S734DV has spe-

cial circuitry to capture data transitions and make them visible

on the LEDs. High-speed bursts of activity, previously unde-

tectable by standard LED circuits, can easily be seen by this

special circuitry.

DATA OUT Indicator

The DATA OUT LED functions identically to the DATA IN

LED except that the LED represents data that is being output

from the unit. This LED has the same high-speed capture cir-

cuitry described in the DATA IN section.

CONTACT Indicator

The CONTACT LED indicates the presence of relay/contact

closure signals. A green CONTACT LED indicates a closed

relay contact, while a red LED indicates an open relay/contact.

ENABLED Indicator

This LED has three states; green indicates a valid mode has

been selected, red indicates an invalid mode (spare or test

mode) has been selected, or flashing red/green indicates that

NO mode has been selected.

RS-485 APPLICATION NOTES

The S734DV is configurable for both full-duplex (4-wire) and

half-duplex (2-wire) operation. It can be used for interfacing

to systems adhering strictly to the RS-485 specification and for

use with systems that use a modified, "fail-safe biased"

RS-485 bus.

Connection

Use high quality twisted-pair wiring, and make sure all con-

nection points are clean and tight. A loose connection on one

of the wires can appear to function, yet cause intermittent

errors: data LEDs may be flashing as signals pass through the

system, but those signals will be corrupt.

Configuration

Fiber Options Universal Data units are designed to work with

virtually any RS-485 system. Unfortunately, some systems

operate on a "modified" version of RS-485; they use failsafe

biasing to pull up/down their bus during a tri-state condition.

In a standard RS-485 system, when a driver on a properly ter-

minated bus goes into tri-state (inactive), the voltage between

the differential outputs should be less than 200 millivolts.

(This is considered "standard offset" in the product instruction

manuals). A differential output tri-state voltage this small can

cause some nonstandard systems to latch up, since they are

designed for much larger, "fail-safe," offsets.

To be able to interface to such equipment, Fiber Options

Universal Data products offer two more "offset" level modes.

That is, the maximum differential input voltage that can be

applied where it will be perceived to be in tri-state.

Of course, the equipment manufacturer does not disclose this

information. In most cases, the Fiber Options unit should be

configured for "standard offset" operation. When the system

is operating properly, the DATA IN and DATA OUT LEDs will

be off when there is no communication (tri-state) and they will

flash when data is being sent or received. In the case where the

link is not functioning properly, (LEDs will most likely not

turn off), change the DATA SELECT switch on the unit to a

higher offset mode. First try 1 V, then 2 V. If simply switching

the mode switch does not prove effective, the offset level may

have to be emulated at one end of the system by using pull-

up/down resistors on the data connector. The S734DV has a

+5 V bias pin and ground pins on the connector for this pur-

pose. Contact equipment manufacturer's technical support for

recommended resistor values and configuration.