25

232001260G(10)

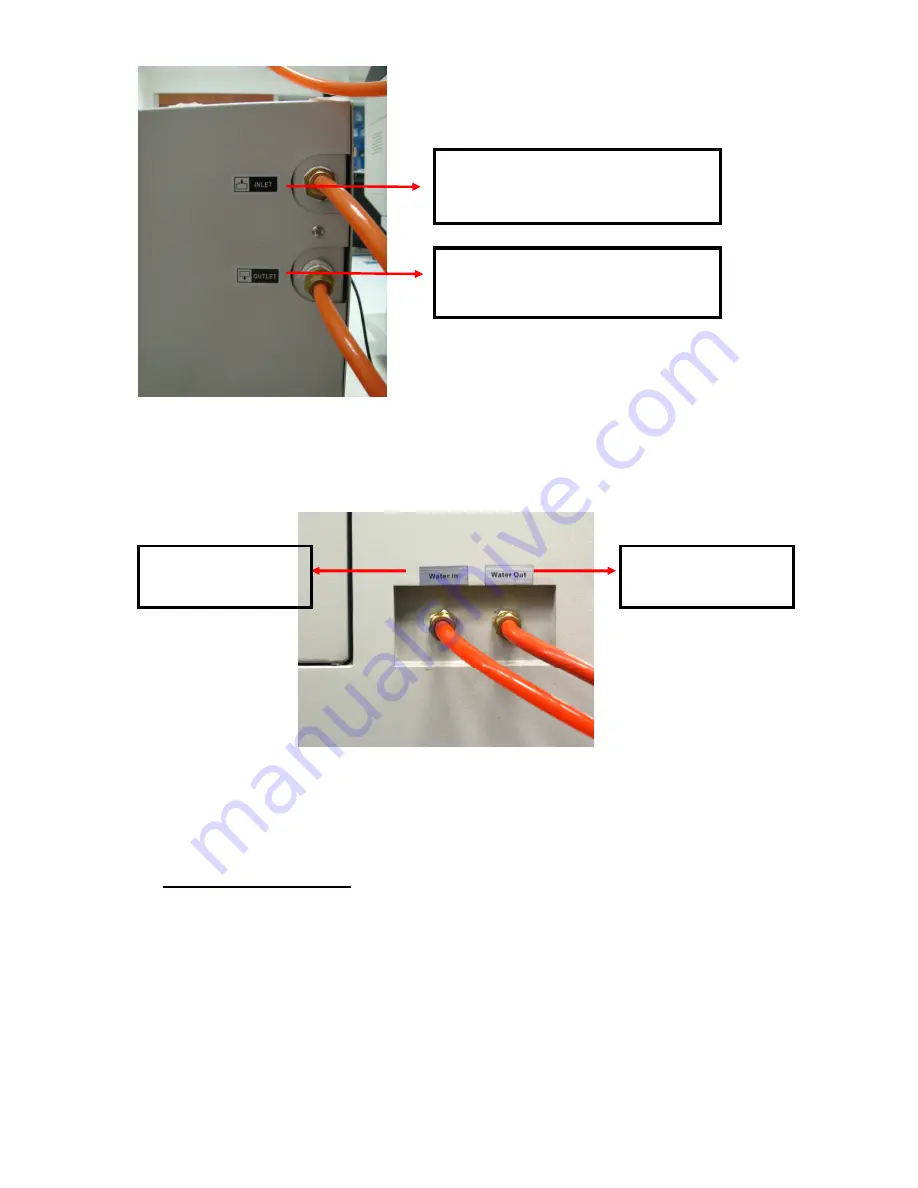

Step 2. Arrange the Outlet and Inlet tubing as follows. Insert the outlet tubing of chiller through

the “Water in” slot opening.

Step 3. Connect the outlet tubing from chiller to the “Water in” connector on machine.

4.1.6 Adjustable Air Nozzle

The Air nozzle can be adjusted to create different distances to the working piece for different air

blowing effect to meet various application demands and prevent dust accumulating on the lens.

NOZZLE ADJUSTMENT:

1)

Clockwise

Nozzle moves closer to the material surface to have a direct and stronger air blowing

force on the material.

2)

Counter-clockwise

Nozzle moves away from the material surface to for a weaker air blowing force on the

material..

3)

Remove Nozzle

If you do not need a strong air blow direct on the material, screw nozzle counter-

clockwise to remove it and have an open air blow.

The outlet tubing of chiller should be

connected to the inlet connector on the

laser machine.

The inlet tubing of chiller should be

connected to the outlet connector on

the laser machine.

Water out connector

on laser tube

Water in connector on

laser tube

Содержание LaserPro X500 III-80Y

Страница 1: ...0 232001260G 10...

Страница 7: ...6 232001260G 10...

Страница 8: ...7 232001260G 10...

Страница 9: ...8 232001260G 10 CDRH Label This label indicates the class level of CDRH...

Страница 31: ...30 232001260G 10...

Страница 32: ...31 232001260G 10...

Страница 37: ...36 232001260G 10...

Страница 38: ...37 232001260G 10...

Страница 82: ...232001260G 10 81...

Страница 83: ...232001260G 10 82...

Страница 103: ...232001260G 10 102 Step 1 Produce the gray level background...

Страница 105: ...232001260G 10 104 Step 2 Produce three dimensional characters...