kept under a suitable protective cap. If the floor is

particularly slippery, wear non-slip shoes.

·

Ensure the power supply system complies with the

standards.

·

Check that the outlet is suitable, complies with the

standards and is equipped with and in-built automatic

protection switch.

·

If the extension lead for the electrical cable is used, this

must feature plug/socket and cable with ear thing, as

stipulated by the standards.

·

Never leave the machine unattended while it is in

motion.

·

Never stop the machine by unplugging it.

·

Do not unplug the machine by pulling the cable.

·

Periodically check the condition of the cable. Replace it

if damaged, this operation must be carried out by

authorized and skilled staff only.

·

Use authorized and coded extension cables only.

·

Protect the cables again high temperatures, lubricants

and sharp edges. Also avoid twisting and knotting the

cable.

·

Do not allow children and strangers to touch the cable

with the plug connected.

·

Should the machine exceed the acoustic pressure level

of 85 dB, suitable protections such as headphones

must be used to protect the hearing.

·

Do not expose the machine to rain or use it in damp or

wet environments. Ensure that cables do not come into

contact with damp or wet areas.

·

During operation of the machine, do not allow children,

people or domestic animals near the machine. Ensure a

safe distance is always kept from the machine.

·

Do not use the machine or its tools for any other uses

than those for which they were designed.

·

On finishing work, thoroughly clean the machine and its

working area.

·

Do not tamper with or try to remove the protections.

·

Only the interventions described in this manual can be

performed on the machine.

·

Only authorized tools and those described in these

operating instructions or included in the Manufacturing

Company’s catalogues must be used. Failure to

observe this advice means operating with unsafe and

potentially dangerous equipment.

·

Operate only in suitably lit environments, in a safe and

stable position, free from any obstructions.

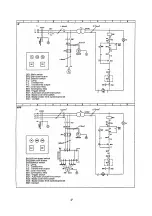

Fig 3-Poaition of the safety signs (pictograms) on the machine.

8

Содержание BS260

Страница 5: ...4...

Страница 6: ...5...

Страница 18: ...17...

Страница 22: ...21...

Страница 23: ...22...

Страница 24: ...23...

Страница 25: ...24...

Страница 26: ...25...

Страница 27: ...NOTES Page 27...

Страница 28: ...Distributed by Garrick Herbert Pty Ltd KIRRAWEE NSW Australia www garrickherbert com au...