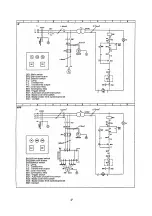

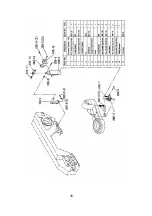

6. Guard opening microswitch ( Fig.8 )

The machine is equipped with a position action

microswitch.

The function of this device is to stop the band from

rotating if the FLYWHEEL GUARD opens ( 4 Fig.1).

7. Limit switch (25 Fig.1)

When the cutting is completed, the band saw is stopped.

4.5 NORMAL CUTTING

After carrying out the operations required for machine

start – up, follow the instructions below:

·

Place the material to be cut in the vice and clamp it

firmly.

·

Press the main switch (7 Fig.1) in order to energize the

machine.

·

Select the required cutting position on the option switch

(7.1 Fig.1).

·

The band saw is now ready to cut.

(1) Grasp the handgrip control (1 Fig.1) and press the

push button (2 Fig.1), in order to start the blade

rotation.

(2) Press the main switch (7 Fig.1), in order to start the

blade rotation.

Rest the blade lightly on the piece to be cut , in order to

avoid breaking the teeth, and execute the cut.

Ensure that the coolant comes out in a sufficient quantity

during the cutting operations. The blade must be well

lubricated.

WARNING!

The machine is equipped with a low voltage electrical

system (24V) with a minimum voltage and thermal

protection device. With this device, if voltage is

disconnected, the machine stops and does not restart

work, the start push button (1 Fig.1) must be activated. In

this way, risks from accidental restarting of the machine

are avoided.

13

Fig.8

CAUTION!

During normal operation if the band saw stops and the

main switch has not been turned to “OFF” (or “0” ) and

press emergency “red mushroom”, determine the cause

for the stop, but take care as this is a hazardous situation.

DANGER!

ALL THE PRELIMINARY OPERATIONS FOR THE CUT

MUST BE CARRIED OUT WHEN THE MACHINE BOW

IS IN STANDBY POSITION AND THE SAW BLADE IS

NOT RATATING.

CUTTING CAPACITY in mm.

Angle

●

▇

▅

0

o

220 220

260

x

110

45

o

150 145

60

o

90 85

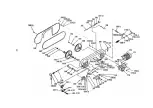

4.6 MITRE CUTTING

It is possible to perform mitre cutting ( max. 60

o

).

To perform this operation, simple loosen the vice lock

lever ( 11 Fig.1) positioned on the machine base and

rotate the head to the angle required; finally tighten the

above mentioned lock lever.

Содержание BS260

Страница 5: ...4...

Страница 6: ...5...

Страница 18: ...17...

Страница 22: ...21...

Страница 23: ...22...

Страница 24: ...23...

Страница 25: ...24...

Страница 26: ...25...

Страница 27: ...NOTES Page 27...

Страница 28: ...Distributed by Garrick Herbert Pty Ltd KIRRAWEE NSW Australia www garrickherbert com au...