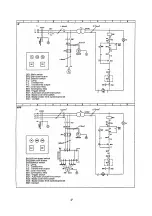

2.2 SAFETY SIGNS

The machine has been designed to incorporate all

possible safety devices for the health and safety of the

operators. However, any residual risks which cannot be

avoided are signaled on the machine by means of

adhesive signs.

The safety signs (pictogram) described in Fig.3 are

positioned on the machine and signal the various

hazardous situations.

Keep them clean and replace them should they come

away or are illegible or damaged.

Refer to Fig.3, read the following information carefully and

memorize it.

1.

Wear safety glasses

. When using the machine

safety eyewear must be used.

2.

Before starting operation

, carefully read the

instructions manual.

3.

Use protective gloves

.

4.

Use ear muffs

.

5.

Before carrying out any maintenance operation

,

stop the machine and consult the instructions manual.

6.

Safety footwear must be worn

. When using the

machine safety footwear must be worn.

7.

High voltage

. Before any maintenance operation,

disconnect the electrical feed.

2.3 CLOTHING

DANGER!

·

Wear suitable clothing. Do not wear loose-fitting clothes,

they could get caught in the rotating parts. Long hair

must be protected by hairnets.

·

When carrying out maintenance and repairs, protective

clothing, cut-proof gloves, and slip and crush resistant

footwear must be worn.

2.4 ECOLOGY AND PLLLUTION

CAUTION!

·

Observe noise pollution guideline and regulations.

·

Observe the laws in force and the specific

manufacturer’s directions for the use and disposal of

7

products used for cleaning and maintaining the

machine.

·

Keep the labels and the instructions for the products

used; if fuel oils or other chemical substances are

swallowed contact Emergency Services immediately,

and consult the relevant labels and/or instructions.

·

Dispose of any remaining packaging in the appropriate

waste recycling or disposal containers.

·

When the machine is dismantled follow the a nti-pollution

guidelines of the country in which the machine is used,

particularly for the lubricants and electrical parts.

2.5 SAFE USE

When using electrical tools or equipment, suitable safety

precautions must be adopted in order to reduce the risks

of fore, electric shocks, and injuries to persons. Before

using the machine, it is therefore recommended to read

the following safety rules carefully and to memorize them.

After having read this manual, keep it carefully.

·

Keep the work area clean and tidy. Untidy areas and

environments increase the risks of accidents.

·

Before starting working, chick that the band saw and its

relevant protections are in perfect working order. Ensure

that the moving parts work correctly, that there are no

damaged or broken elements and that the machine is

free of obstructions. Damaged or broken parts should be

repaired or replaced by authorized and skilled staff.

·

Repairing or having parts repaired by personnel not

authorized by the Manufacturing Company, in addition to

risking cancellation of the guarantee, means operating

with unsafe and potentially dangerous equipment.

·

While the band saw is in use, do not touch its moving

parts.

·

All checks, controls, cleaning and maintenance

operations, changing or replacement of parts must be

carried out with the machine off and unplugged.

·

It is absolutely forbidden to allow children, unauthorized

personnel, inexperienced persons or persons not in

good health to touch or use the machine.

·

While using the machine, it is recommended to wear

suitable clothing. It is imperative to avoid wearing

jewellery or baggy clothing with loose parts that could

become entangled in the rotating or moving parts

resulting in injuries to the operator. Long hair should be

Содержание BS260

Страница 5: ...4...

Страница 6: ...5...

Страница 18: ...17...

Страница 22: ...21...

Страница 23: ...22...

Страница 24: ...23...

Страница 25: ...24...

Страница 26: ...25...

Страница 27: ...NOTES Page 27...

Страница 28: ...Distributed by Garrick Herbert Pty Ltd KIRRAWEE NSW Australia www garrickherbert com au...