SECTION 4

INSTRCTIONS FOR USE

4.1 BEFORE USE

WARNING!

Before starting up the machine the operator must read

and assimilate this entire manual, particularly Section 2

which deals with safety.

Furthermore, before starting work, check that the machine

is in order and that all the parts subject to wear and

deterioration are in perfect condition.

4.2 USE

The band saw has been exclusively designed and

manufactured for cutting ferrous materials with tubular,

open or filled sections.

Use of the machine for cutting other materials or for

different processing that do not comply with the uses

described in this manual, is not only to be considered

improper and prohibited, but also release the

Manufacturing Company from any responsibility, both

direct and indirect.

Before inserting the plug into the socket, ensure that the

voltage corresponds to that marked on the identification

plate (17 Fig.1).

4.3 OPERATION

·

Connect the machine plug and switch on the machine.

·

Turn the total switch (8 Fig.1). A pilot light switches (8.1

Fig.1) on to signal that the machine is energized.

·

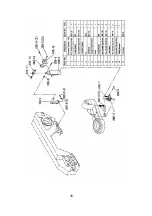

Check that the band tensioning microswitch is pressed

down, otherwise the machine will not work(1 Fig.7).

·

Raise the saw bow, ensure setting bracket is

disconnected from limit switch.

Start

1. Turn Emergency (red mushroom) (6 Fig.1).

2. Start the band saw.

·

Turning the option switch to position “handgrip

control” (7.1 Fig.1), press the button (2 Fig.1).

·

Turning the option switch to position “ main switch”

(7.1 Fig.1), press the main switch (7 Fig.1).

Stop

To stop the band saw

12

·

Push the Emergency (red mushroom) (6 Fig.1).

·

Turn the total switch (8 Fig.1) to “OFF” (or position “0”).

Fig.7

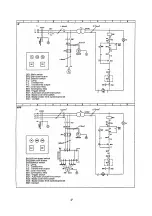

4.4 CONTROL DEVICES

The machine is equipped with the following control

devices:

1. Total switch (8 Fig,1)

The function of this switch is to power supply the machine.

When it is on, a pilot light indicates that the machine is

energized.

(3

∽

Motor only ) (“0” position: the saw blade does not

rotate; POSITION “1”: This is the position of the lowest

speed; POSITION “2”: This is the position of the fastest

speed.)

2. Emergency stop (6 Fig.1)

The machine is equipped with an emergency push button

used to stop the machine in an emergency. The stop push

button must be released before the machine is restarted

after an emergency stop.

3. Option switch (7.1 Fig.1)

The function of this switch is option circuit. (“handgrip

control” or “main switch”)

4. Main switch (7 Fig.1)

Press this switch, the band saw is running.

5. Handgrip with control push button (1 Fig.1)

The handgrip control (the operator must e present ) is

used to lift or lower the bow, in order to carry out the

cutting operation. This handgrip consists of a tube,

secured to the machine head: the handgrip control with its

push button is fitted to the end of the tube.

Press the button(2 Fig.1) to star rotating the saw blade;

release the button to stop it.

Furthermore, the handgrip is equipped with a safety

device to guard against accidental star up.

Содержание BS260

Страница 5: ...4...

Страница 6: ...5...

Страница 18: ...17...

Страница 22: ...21...

Страница 23: ...22...

Страница 24: ...23...

Страница 25: ...24...

Страница 26: ...25...

Страница 27: ...NOTES Page 27...

Страница 28: ...Distributed by Garrick Herbert Pty Ltd KIRRAWEE NSW Australia www garrickherbert com au...