11

Step 3

– Initial running and adjusting camera lateral position

When you are happy you have a good template match press the button

labelled “Manual” again to

return to the normal working screen ready for tracking. You can be sure that the machine is ready

for tracking if a line of blue crosses has appeared down the centre of the display.

Note

For initial set up runs almost all the crosses should be coloured blue and form a relatively straight

vertical line. If this is not the case, or a triangular tracking warning symbol is displayed, either the

machine is not correctly set up, or crop rows are not sufficiently well defined for initial running.

If tracking appears good set off slowly into the crop. The implement should quickly align with crop

rows. It is likely that after a short distance it will have settled at a small lateral offset. Small offsets

can be corrected using the fine offset facility available from the working screen. Buttons labelled

with left and right arrows adjust fine offset whose current position is displayed centrally below the

live video image. Each press of an arrow key biases the side shift in steps of 1cm

(3/8”). Continue

down the field stopping occasionally to check lateral position. If the required fine offset exceeds

the available number of steps the camera should be physically moved as described below and step

3 repeated.

It is the operator's responsibility to decide at which point the vision guidance system

becomes 'lost'. If the system losses track of crop rows the operator should carefully guide

the implement through to the next good reference.

Garford accept no responsibility for damage to or loss of crop whatsoever.

After approximately 200m of running Robocrop should have learnt camera alignment

(“camera

skew”) and lateral bias should therefore have stabilised. If fine offset is set to greater than two

steps, we recommend physically moving the camera along the toolframe by the equivalent

distance and resetting fine offset to zero.

Tip

If fine offset is set to the left, then the camera should be moved right as viewed from behind looking

forward.

Once you are confident that Robocrop is tracking accurately and reliably forward speed can be

increased. Working speeds up to 12 kph can be accommodated with Robocrop, however the

mechanical interaction of shares and shields on the soil and its effect upon plants will determine if

this is achievable.

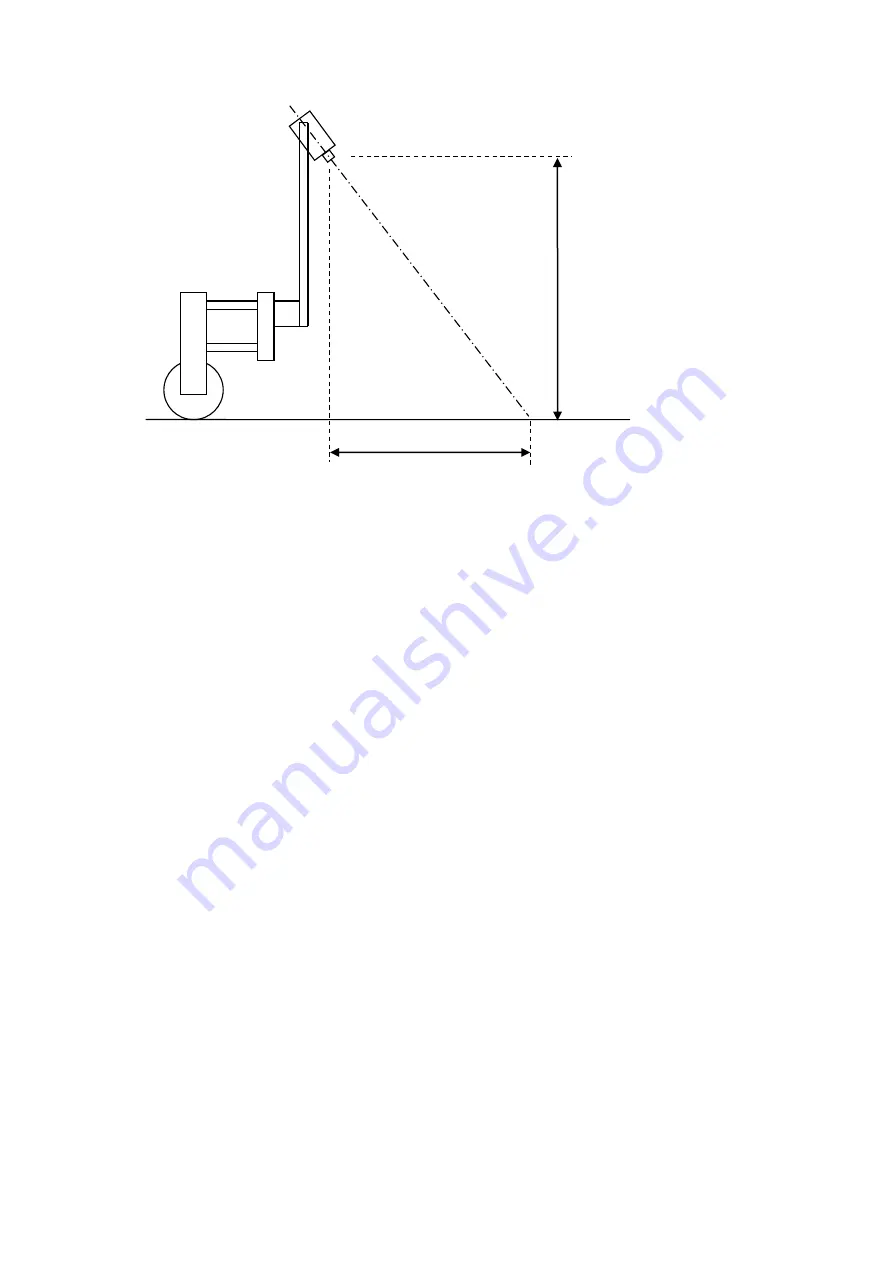

“Camera

height

” (m)

“Look ahead” distance (m)