3–600 Page 10

Never tighten liner jack screws while

pump is running. If the screws are

drawn up too tight, enough pressure

can be put on the packing to crush the

liner. This ruins the liner, is apt to ruin

the piston and can cause piston rod

breakage.

Whenever the cylinder head is removed for any reason,

the liner jack screws must be backed out. Jack screws

should be greased to increase life of screws and cylin-

der heads and also to prevent rust formation.

When the cylinder head is replaced, the head to cylin-

der stud nuts should be tightened completely. AFTER

the head nuts are tight, the liner jack screws should be

adjusted against the liners and the locknuts tightened.

Be sure packing is installed under set screw nuts to pre-

vent leakage

Some pumps are equipped with a clamp located

against the end of the liner and serves as a face for the

set screws to bear against. For the proper tightening

torques refer to torque table, page 18.

FLUID END PARTS – Standard procedure for shipping

pumps from the Factory is with valves, pistons, liners,

piston rods and packing installed. These fluid end ex-

pendable parts are shipped unassembled only when

requested by the customer.

FLUID CYLINDER LINERS – Liners should be

installed in accordance with instructions given under

heading ”Fluid Cylinder Liner Packing”, page 9. Clean

liners thoroughly and grease the outside diameter be-

fore installing. Liner jack screws should be tightened as

uniformly as possible.

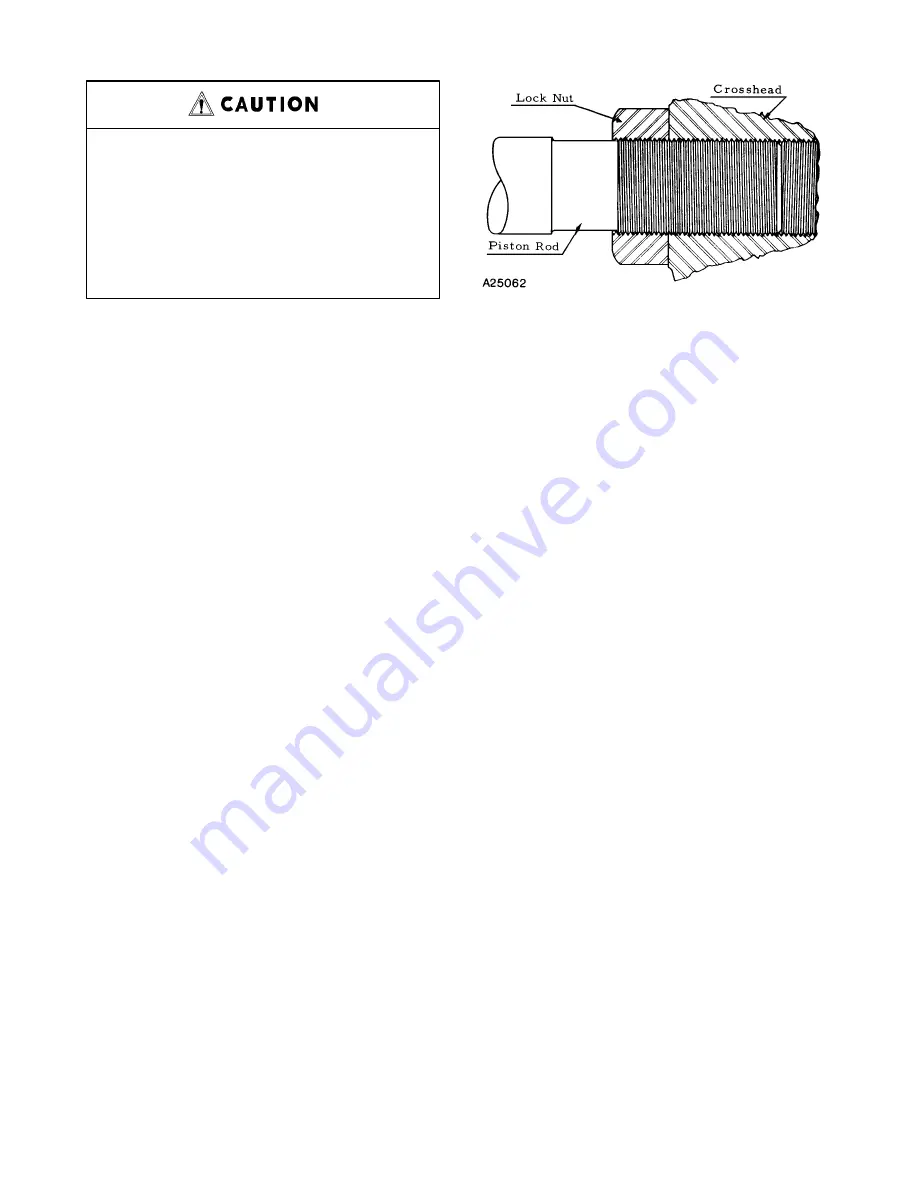

PISTON RODS – Pistons should be assembled on the

rod taper WITH THE THIN NUT NEXT TO THE PIS-

TON HUB AND THE THICK NUT ON THE OUTSIDE.

This is important as the outer nut carries the load. Slush

service rods use one elastic collar–type locknut per

rod. Rods should be threaded into the crosshead as

shown in FIGURE 6, leaving approximately one thread

of the locknut over the relieved portion of the rod as a

protection to the threads.

FLUID VALVES – Valves are easily installed in their in-

dividual valve pots. Care should be exercised to tighten

the valve cover nuts as uniformly as possible, tighten-

ing each nut a little at a time until all are tight. Valve

FIGURE 6 – PISTON ROD

seats and the bore in the deck must be perfectly clean

and free from oil or grease.

Valve seats can be removed with a puller which can be

purchased from Gardner Denver Machinery Inc.

STARTING A NEW PUMP – Pumps are shipped from

the factory without oil in the crankcase. The hood

should be removed and the power end examined and

cleaned if necessary. The pump may have been in stor-

age or in the yard for some time and as a consequence

dirt may have entered the crankcase. Parts may have

been robbed from the pump during storage and not re-

placed. All nuts and screws should be tightened.

The jackshaft bearings have been supplied with grease

at the factory and no grease should be added at this

time, unless bearings have been disturbed.

Be sure all valves in the discharge line are open. No

valve should be installed between the pump and pres-

sure relief valve in discharge line.

To prevent excessive wear on the fluid pistons and

packing when starting, remove a suction valve cover

plate on each side of the fluid end and prime the pump.

Pump should be started slowly, if possible, and should

be operated for several hours with practically no dis-

charge pressure. Check oil level as it may be neces-

sary to add a small quantity of oil to compensate for that

adhering to the walls of the crankcase and the moving

parts. The pump may then gradually be brought up to

full speed and full working pressure. Watch for undue

heating or abnormal noise in the working parts. Check

all joints in the suction line to be sure there are no air

leaks.

Make certain pump is rotating in the correct direction.

Refer to FIGURE 7, page 11.

Содержание FXF - 5"

Страница 17: ...3 600 Page 11 FIGURE 7 ROTATION OF ECCENTRIC PREFERRED ROTATION OF ECCENTRIC...

Страница 27: ......