SMART 200 TIG PULSE

33

4.2. Troubleshooting

•

Before arc welding machines are dispatched from the factory, they have already been debugged accurately.

So forbid anyone who is not authorized by our company to do any change to the equipment!

•

Maintenance course must be operated carefully. If any wire becomes flexible or is misplaced, it maybe

potential danger to user!

•

Only professional maintenance personal who is authorized by our company could overhaul the machine!

•

Guarantee to shut off the arc welding machine’s power before turn on the outline of the equipment!

•

If there is any problem and has no the authorized professional maintenance personal of our company, please

contact local our company agent or the branch company!

If there are some simple troubles of SMART 200 welding machine, you can consult the following overhauling chart:

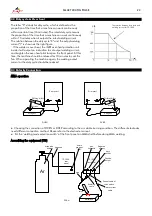

S/N

Troubles

Reasons

Solution

1

Turn on the power source,

and fan doesn’t work, but

the power light is not on.

The power light damaged or connection

is not good

Test and repair the inside circuit of

power light

The transformer of power is broken

Repair or change the transformer

Control PCB failures

Repair or change the control PCB

2

Turn on the power source,

and the power light is on, but

fan doesn’t work.

There is something in the fan

Clear out

The start capacitor of fan damaged

Change capacitor

The fan motor damaged

Change fan

3

Turn on the power source,

and the power light is not on

and fan doesn’t work.

No power supply input

Test the power supply input

The fuse on the rear panel is broken

Change the fuse (3A)

4

No no-load voltage output

(MMA)

The machine is damaged

Check the main circuit and the

PCBs(Pr1)

5

Arc can not

be ignited

(TIG)

There is

spark on the

HF igniting

board.

The welding cable is not connected with

the two output of the welder.

Connect the welding cable to the

welder’s output.

The welding cable damaged.

Repair or change it.

The earth cable connected unstably.

Check the earth cable.

The welding cable is too long.

Use an appropriate welding cable.

There is oil or dust on the workpiece.

Check and remove it.

The distance between tungsten electrode

and workpiece is too long.

Reduce the distance (about 3mm).

The distance between the discharger is

too short.

Adjust this distance (about 0.7mm).

The malfunction of the welding gun

switch.

Check the welding gun switch, control

cable and aero socket.

6

HF striking arc can not be

stopped

Check Pr2

Repair or change it.

7

No gas flow (TIG)

Gas cylinder is close or gas pressure is

low

Open or change the gas cylinder

No controlling electromagnetic valve

signal

Repair or change the pulse board

Something in the valve

Remove it

Electromagnetic valve is damaged

Change it

8

When welding, it is hard to

strike arc or easy to

stick.(MMA)

Connector is loose or connection is not

good.

Check and screw it.

There is oil or dirty on the workpiece.

Check and clear it.

9

The welding current can not

be adjusted

The welding current potentiometer on the

front panel connection is not good or

damaged

Repair or change the potentiometer

The control signal of the pulse board is

wrong

Repair or change the pulse board

10

The penetration of molten

pool is not enough.

The welding current is adjusted too low

Increase the welding current

The arc is too long in the welding process

Use the short-arc operation