16

Governors America Corp. © 2021 Copyright All Rights Reserved

Enhanced Electronic Governor EEG7000 with GAConfig Tool 8-2021-D6

PIB1009

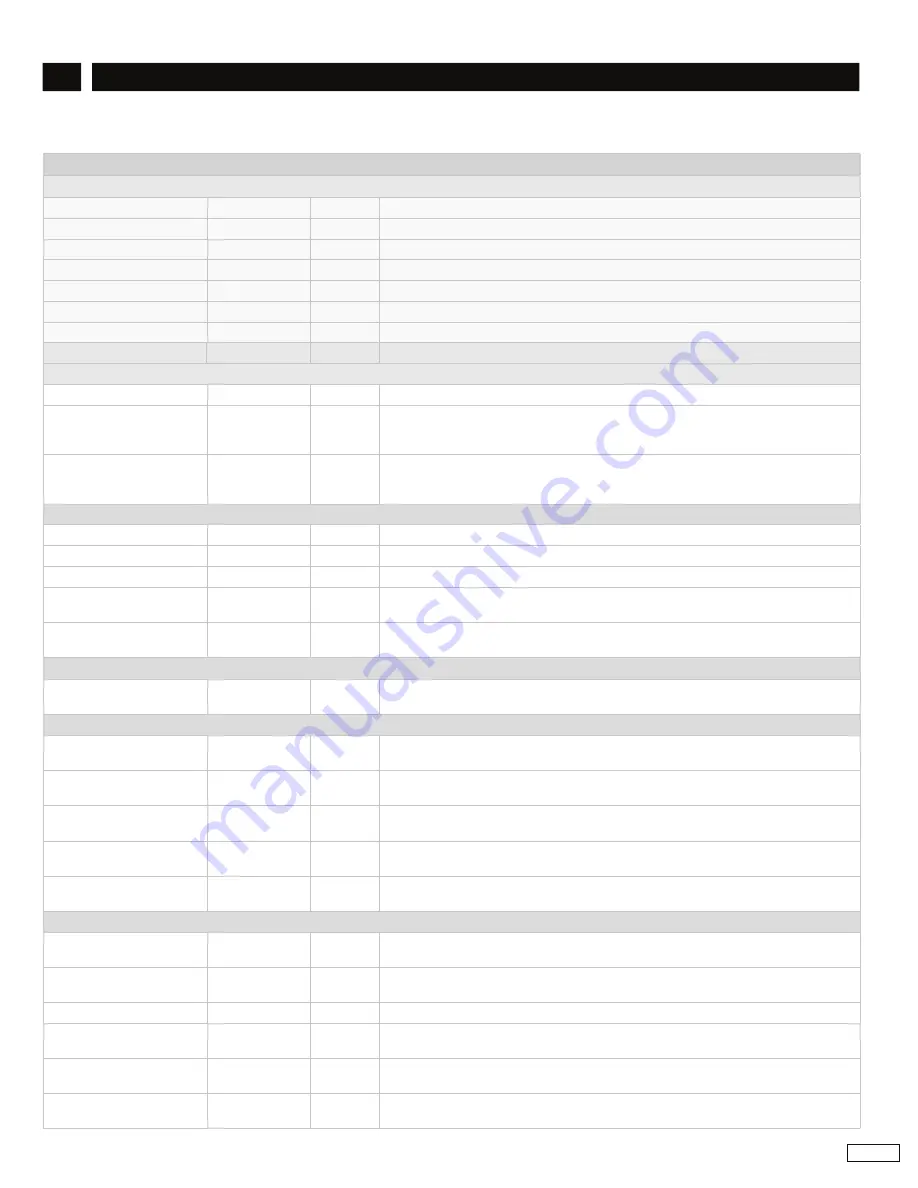

QUick confiGUration - engine tuning

System Status - engine and actuator - Displays current status similar to Dashboard

Magnetic Pickup Frequency Display only

Hz

Current engine speed

Actual Engine Speed

Display only

rpm

Current engine speed

Desired Engine Speed

Display only

rpm

Set governing speed

Operator Requested Speed

Display only

rpm

Requested governing speed

Selected Speed Mode

Display only

Speed 1, 2, 3, Variable

Actuator Duty Cycle

Display only

%

Actuator duty cycle

Actuator Current

Display only

A

Current draw of actuator

Parameter

min - max

DefaUlt noteS

System Setup

Flywheel Teeth

60 - 250

120

Number of teeth on the flywheel.

The system can govern up to 12000 Hz.

Overspeed

150 - 6000*

1800

Set rpm to cause automatic actuator shut down. Set value low enough to prevent

mechanical damage but high enough to allow realistic load rejection speeds without

stopping engine. Begin by setting at no more than 25 % above rated speed.

Fuel Limit

0 - 100 %

100

Maximum fuel (actuator duty cycle) allowed during governing. Prevents over fueling

after engine has started. During normal starting cycles and short load step the function

will not engage since there is a 1 second delay.

Start-Up / ramp control

Actuator Start Fuel

0 - 100 %

100

Actuator start point during cranking.

Actuator Ramp Rate

1 - 100 %/s

10

Fuel (actuator duty cycle) ramp rate during cranking.

Starter Cutoff

100 - 1000 rpm

400

Crank termination speed in rpm.

Acceleration

25 - 2000 rpm/s

300

Controls rate of acceleration in engine speed. A lower value rpm/s allows for a gradual

increase in engine speed while a larger value of rpm/s provides faster acceleration

Deceleration

25 - 2000 rpm/s

300

Controls rate of deceleration in engine speed. Lower rpm/s allows gradual decrease in

response to engine speed while higher rpm/s create more rapid deceleration.

fixed Speed

Speed 1

Speed 2, 3

0 - 6000*

150 - 6000*

1500

1500

Set engine speeds.

variable Speed

Variable Speed Input Mode

4 - 20 mA or

0 - 5 V DC

0 - 5 V DC Sets variable speed input signal to 0 - 5 V DC or 4 - 20 mA

Speed Minimum

Speed Maximum

150 - 6000*

150 - 6000*

1500

1500

Minimum and maximum speed settings.

Variable Speed Start Gain

Variable Speed End Gain

1 - 100

0 - 100

50

50

Gain used when at the minimum speed while in variable speed.

Gain used when at the maximum speed while in variable speed.

Input Minimum

0 - 75 %

0

Sets variable input start position based on current value. Range: 0 to 75 % and must be

25 % apart from end position. Use the Calibrate button to set automatically.

Input Maximum

25 - 100 %

100

Sets variable end position based on the current value. Range: 0 to 75 % and must be

25 % apart from end position. Use the Calibrate button to set automatically.

tuning

Gain 1, 2, 3 (P)

1 - 100

50

Gain determines how fast the controller responds to transient load changes or when a

load disturbance occurs. Applicable to related Speed 1, 2, or 3.

Stability (I)

0 - 100

50

Stability changes steady state response of the engine. Increasing stability brings the

system to steady state faster and decreasing causes a gradual transition.

Deadtime (D)

Low - High

High

Deadtime

Lead Circuit

Select -

Deselect

Select

Lead Circuit increases the range of Gain adjustment increasing the responsiveness of

the governor. Select Lead Circuit if slow or moderate hunting and higher Gain.

Light Force Governing

Select -

Deselect

Deselect

Light Force Governor improves performance when controlling small or low current actu-

ators (GAC T1 ATB, ALR/ALN, 100/103/104 series and normally closed actuators).

Speed Anticipation

Select -

Deselect

Deselect

Speed anticipation reduces rpm recovery time during high load transients and requires

both no load (NLCU) and full load current (FLCU) values are entered.

GAC

onfig

TOOl - SETTING All PARAmETERS

The

gives you access to all the parameters from one menu location. Parameters are grouped by function

and relate directly to the GAConfig Tool groups on other tabs. The menu does not display you all the error messages the core menus

do. Parameter values may be updated by the software if they interfere with other parameters.

14