En-6

CAUTION

• There should be no gaps between the insulation and the unit.

• After checking for gas leaks (refer to the Installation Manual of the outdoor unit),

perform this section.

• Install heat insulation around both the large (gas) and small (liquid) pipes. Failure to

do so may cause water leaks.

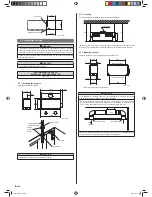

5. INSTALLING DRAIN PIPES

5.1. Installing drain pipes (Ceiling concealed type)

CAUTION

• Install the drain pipe in accordance with the instructions in this Installation Manual

and keep the area warm enough to prevent condensation. Problems with the piping

may lead to water leaks.

Install the drain pipes according to the measurements given in the following

fi

gure.

Flange positions for connecting the drain pipes.

139

123

108

41

208

356

371

Main drain pipe

ø25.4 (O.D.)

Safety drain pipe

ø25.4 (O.D.)

Unit : mm

CAUTION

• This UNIT has drain ports in two locations. Follow the procedure in the figure to

connect drain pipes to each of them.

• Be sure to properly insulate the drain pipes.

Use general hard polyvinyl chloride pipe (VP25) and connect it with adhesive (polyvinyl

chloride) so that there is no leakage.

Do not perform air bleeding.

(1) Main drain pipe

Provide one trap on the main drain pipe near the indoor unit.

H

1

H

2

Trap

Unit

H

1

= 100 mm (approx.)

H

2

= 50-100 mm

Drain pipe (main)

(2) Safety drain

There is no need to provide a trap for the safety drain pipe. If the safety drain pipe is

connected to the main drain pipe, make the connection below the trap on the main drain

pipe.

Drain pipe (main)

Drain pipe (safety)

Unit

•

Once installation is complete, check the

fl

ow of the drain water.

(1) Detach the caps and plugs from the pipes.

(2) Centering the pipe against port on the indoor unit, turn the

fl

are nut with your hand.

Flare nut

Connection pipe

(small)

Connection pipe

(large)

Flare nut

(3) When the

fl

are nut is tightened properly by your hand, hold the body side coupling

with a separate spanner, then tighten with a torque wrench. (See the table below for

the

fl

are nut tightening torques.)

CAUTION

• Hold the torque wrench at its grip, keeping it at a right angle with the pipe, in order to

tighten the

fl

are nut correctly.

• Tighten the

fl

are nuts with a torque wrench using the speci

fi

ed tightening method.

Otherwise, the

fl

are nuts could break after a prolonged period, causing refrigerant to

leak and generate a hazardous gas if the refrigerant comes into contact with a

fl

ame.

• Connect the piping so that the control box cover can easily be removed for servicing

when necessary.

• In order to prevent water from leaking into the control box, make sure that the piping

is well insulated.

Tighten with 2 wrenches.

Holding wrench

Flare nut

Connection pipe

Torque wrench

Indoor unit pipe

(Body side)

Flare nut [mm (in.)]

Tightening torque [N·m (kgf·cm)]

6.35 (1/4) dia.

16 to 18 (160 to 180)

9.52 (3/8) dia.

32 to 42 (320 to 420)

12.70 (1/2) dia.

49 to 61 (490 to 610)

15.88 (5/8) dia.

63 to 75 (630 to 750)

19.05 (3/4) dia.

90 to 110 (900 to 1,100)

4.4. Installing heat insulation

After checking for gas leaks, insulate by wrapping insulation around the two parts (Gas

and Liquid) of the indoor unit coupling, using the coupler heat insulation.

After installing the coupler heat insulation, wrap both ends with vinyl tape so that there is

no gap.

Secure both ends of the heat insulation material using nylon fasteners.

Coupler heat insulation (Small)

Coupler heat insulation (Large)

Indoor unit side

9379123037-02.indb 6

9379123037-02.indb 6

7/4/12 3:47 PM

7/4/12 3:47 PM