En-13

9. TEST RUN

CHECK ITEMS

(1) Is operation of each button on the remote controller normal?

(2) Is the drain normal?

(3) Is there any abnormal noise and vibration during operation?

• Do not operate the air conditioner in test run for a long time.

[OPERATION METHOD]

• For the operation method, refer to the operating manual.

(1) Stop the air conditioner operation.

(2) Press the MODE button and the FAN button simultaneously for 2 seconds or more to

start the test run.

Test run display

(3) Press the START/STOP button to stop the test run.

If “C0” appears in the unit number display, there is a remote controller error. Refer to the

installation manual included with the remote controller.

Unit number

Error code

Content

Incompatible indoor unit is connected

Indoor unit

↔

remote controller communication

error

10. CHECK LIST

Pay special attention to the check items below when installing the indoor unit(s). After

installation is complete, be sure to check the following check items again.

CHECK ITEMS

If not performed correctly

CHECK BOX

Has the indoor unit been

installed correctly?

Vibration, noise, indoor unit

may drop

Has there been a check for

gas leaks (refrigerant pipes)?

No cooling, No heating

Has heat insulation work been

completed?

Water leakage

Does water drain easily from

the indoor units?

Water leakage

Are the wires and pipes all

connected completely?

No operation, heat or burn

damage

Is the connection cable the

speci

fi

ed thickness?

No operation, heat or burn

damage

Are the inlets and outlets free

of any obstacles?

No cooling, No heating

After installation is completed,

has the proper operation and

handling been explained to

the user?

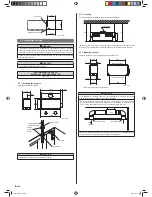

11. OPTIONAL KIT INSTALLATION (OPTION)

WARNING

Regulation of cable differs from each locality, refer in accordance with local

rules.

This air conditioner can be connected with the following optional kits.

Option type

Connector No.

UTY-XSZX (Remote sensor unit)

CN8

UTD-ECS5A (External input)

CN114

UTD-ECS5A (External output)

CN115

UTD-ECS5A (Preparation)

CN5, CN106

(CN8)

(CN115)

(CN114)

Remote controller

cable

Connection cable

(to outdoor unit)

(CN106)

(CN5)

12. CUSTOMER GUIDANCE

Explain the following to the customer in accordance with the operating manual:

(1) Starting and stopping method, operation switching, temperature adjustment, timer, air

fl

ow switching, and other remote controller operations.

(

2) Air

fi

lter removal and cleaning, and how to use the air louvers.

(3) Give the operating and installation manuals to the customer.

9379123037-02.indb 13

9379123037-02.indb 13

7/4/12 3:47 PM

7/4/12 3:47 PM