En-3

2.3. Accessories

WARNING

• For installation purposes, be sure to use the parts supplied by the manufacturer or

other prescribed parts.

The use of non-prescribed parts can cause serious accidents such as the unit to fall,

water leakage, electric shock, or

fi

re.

• The following installation parts are furnished. Use them as required.

• Keep the Installation Manual in a safe place and do not discard any other accessories

until the installation work has been completed.

Do not discard any accessories needed for installation until the installation work has

been completed.

Name and Shape

Q’ty

Application

Operating Manual

1

Installation Manual

1

(This book)

Special nut A

(Large flange)

4

For suspending the indoor unit from

ceiling

Special nut B

(Small flange)

4

Coupler heat insulation (Large)

1

For indoor side pipe joint

(Gas pipe)

Coupler heat insulation (Small)

1

For indoor side pipe joint

(Liquid pipe)

Cable tie (Small)

1

For fixing the remote controller

cable

Remote controller

1

Screw

(M4 × 16)

2

For installing indoor unit remote

controller

Remote controller cable

1

For connecting the remote controller

2.4. Optional parts

Parts name

Model No.

Application

Simple remote controller

UTY-RSN*M

For air conditioner operation

Wired remote controller

UTY-RNN*M

For air conditioner operation

Remote sensor unit

UTY-XSZX

Room temperature sensor

External connect kit

UTD-ECS5A

For control input/output port

Long life

fi

lter

UTD-LF60KA

3. INSTALLATION WORK

3.1. Selecting an installation location

Especially, the installation place is very important for the split type air conditioner be-

cause it is very dif

fi

cult to move from place to place after the

fi

rst installation.

WARNING

• Select installation locations that can properly support the weight of the indoor. Install

the units securely so that they do not topple or fall.

CAUTION

• Do not install the unit in the following areas:

• Area with high salt content, such as at the seaside.

It will deteriorate metal parts, causing the parts to fail or the unit to leak water.

• Area

fi

lled with mineral oil or containing a large amount of splashed oil or steam,

such as a kitchen.

It will deteriorate plastic parts, causing the parts to fail or the unit to leak water.

• Area that generates substances that adversely affect the equipment, such as

sulfuric gas, chlorine gas, acid, or alkali.

It will cause the copper pipes and brazed joints to corrode, which can cause

refrigerant leakage.

• Area that can cause combustible gas to leak, contains suspended carbon

fi

bers or

fl

ammable dust, or volatile in

fl

ammables such as paint thinner or gasoline.

If gas leaks and settles around the unit, it can cause a

fi

re.

• Area where animals may urinate on the unit or ammonia may be generated.

• Do not use the unit for special purposes, such as storing food, raising animals,

growing plants, or preserving precision devices or art objects.

It can degrade the quality of the preserved or stored objects.

• Do not install where there is the danger of combustible gas leakage.

• Do not install the unit near a source of heat, steam, or

fl

ammable gas.

• Install the unit where drainage does not cause any trouble.

• Install the indoor unit, outdoor unit, power supply cable, transmission cable, and

remote controller cable at least 1 m away from a television or radio receivers. The

purpose of this is to prevent TV reception interference or radio noise.

(Even if they are installed more than 1 m apart, you could still receive noise under

some signal conditions.)

• Decide the mounting position with the customer as follows:

(1) Install the indoor unit in a location having suf

fi

cient strength to support the weight of

the indoor unit.

(2) The inlet and outlet ports should not be obstructed; the air should be able to blow all

over the room.

(3) Leave the space required to service the air conditioner.

(4) Locate where the air can be distributed evenly throughout the room by the unit.

(5) Install the unit where connection to the outdoor unit is easy.

(6) Install the unit where the connection pipe can be easily installed.

(7) Install the unit where the drain pipe can be easily installed.

(8) Install the unit where noise and vibration is not ampli

fi

ed.

(9) Take servicing, etc., into consideration and leave the spaces. Also install the unit

where the

fi

lter can be removed.

(10) Providing as much space as possible between the indoor unit and the ceiling will

make work much easier.

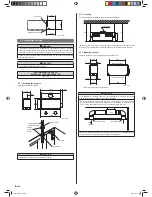

3.2. Installation dimension

Install at least 20mm from the ceiling.

2500 or more

(When no

ceiling)

Floor

(Service space)

Unit : mm

450

20 or more

(For maintenance)

(1) Maintenance work of the control box is possible with the maintenance hole of the

measurement shown in the

fi

gure.

(2) If maintenance work is to be done from the bottom side, the maintenance hole needs

to be larger than the outside dimension of the indoor unit.

(3) If maintenance work is to be done from the top, keep the space of the more than

500 mm between the indoor unit and ceiling.

9379123037-02.indb 3

9379123037-02.indb 3

7/4/12 3:47 PM

7/4/12 3:47 PM