9

3 Applicable Encoder

CAUTION

•

Check the encoder specification again before operating the inverter. Improper encoder specification may cause

unexpected inverter operation or device operation.

There is a risk of accident or injury.

3.1 Specifications of Applicable Encoder

Table 3.1 Specifications of Applicable Encoder

Item Specifications

Incremental signals

2 sinusoidal signals A and B as sine and cosine with 2048 periods per

revolution

Rotor Position Detection

2 sinusoidal signals C and D as sine and cosine with one period per revolution

+5 VDC (5 VDC ±5%/300 mA)

Application

encoder

Encoder power supply

Encoder model

HEIDENHAIN ECN1313 or its equivalent

3.2 Encoder Installation and Signal

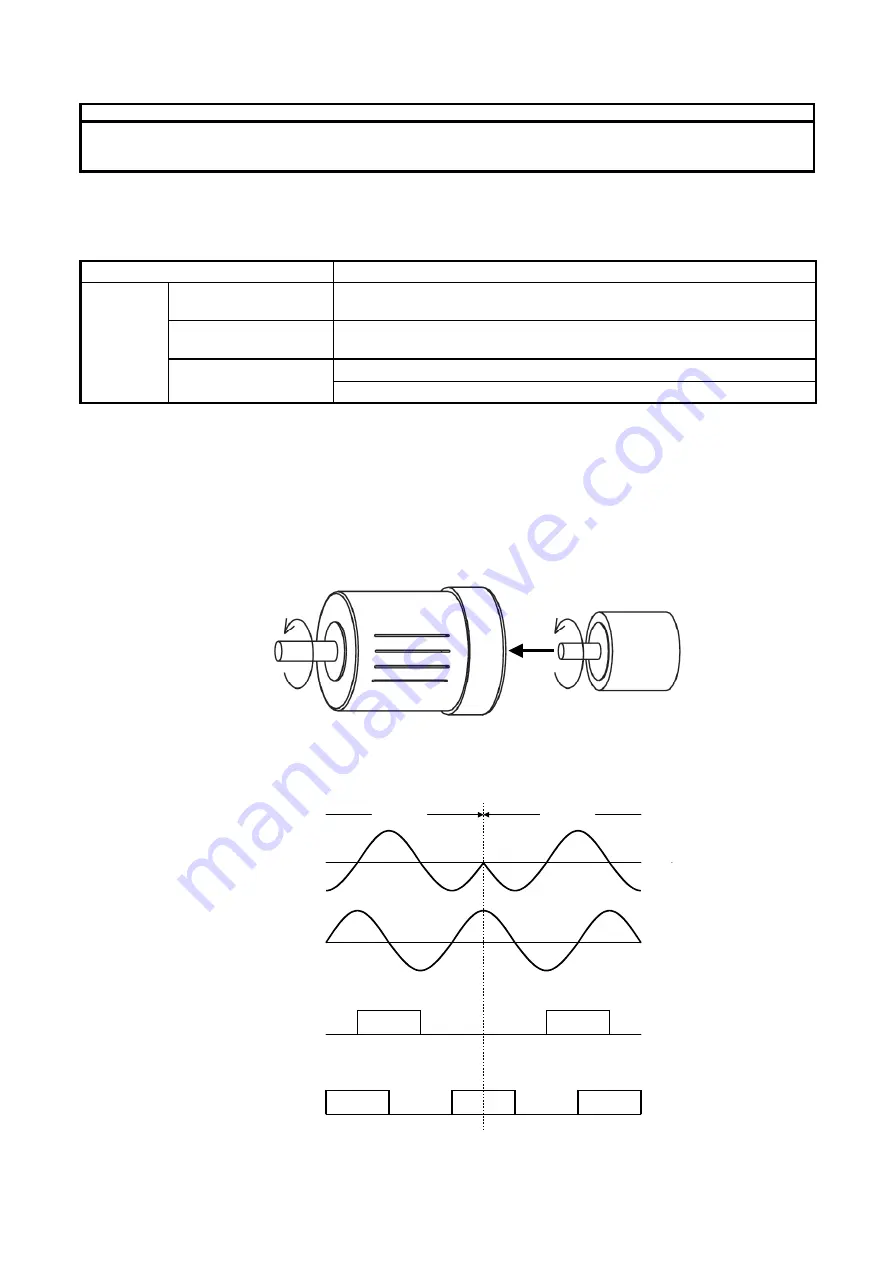

The encoder shall rotate in the direction shown in Figure 3.1 when terminal FWD is ON.

Encoder output pulse is shown in Figure 3.2. Connect the encoder directly to the motor using a coupling.

If the encoder rotation is different from that shown in Figure 3.1, interchange V with W of inverter output.

The rotational direction of IEC standard motors is opposite to that shown in Figure 3.1.

Motor

Encoder

Rotational direction when terminal FWD is ON.

Driving side

Figure 3.1 Motor and Encoder Rotational Direction when Terminal

FWD is ON

FWD ON

REV ON

FPA

FPB

PA+,PA-Differential

input signal

PB+,PB-Differential

input signal

Figure 3.2 Definition of Terminal FWD ON/REV ON